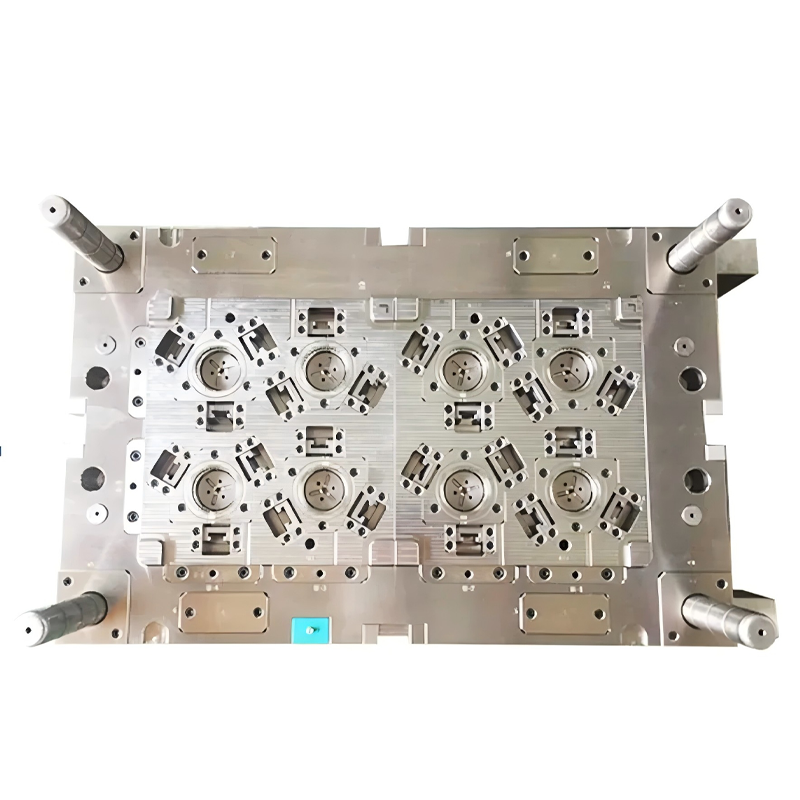

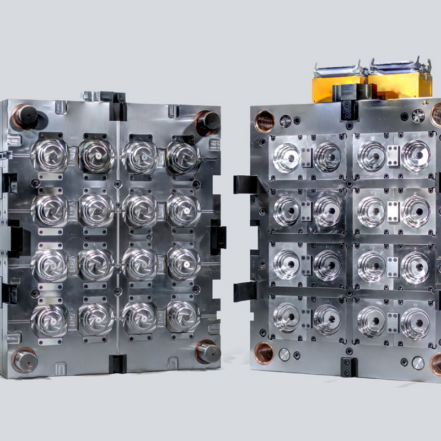

Multi-cavity injection mould tools are advanced molds designed to produce multiple identical parts in a single injection cycle, optimizing production efficiency and reducing costs. These tools feature several cavities, each capable of producing a part simultaneously, which is especially beneficial for high-volume manufacturing. The multi-cavity design allows for faster turnaround times, improved consistency, and lower per-part costs, making it ideal for industries such as automotive, consumer electronics, and medical devices. By maximizing the use of available mould space and minimizing cycle times, multi-cavity injection mould tools help manufacturers meet demanding production schedules while maintaining high-quality standards.

Basic Information

Mold Type: Plastic Injection Mold

Mold Material Options:P20, 718, 738, NAK80, S136

Mold Base Standards: HASCO, DME, MISUMI, JIS, LKM, etc.

Mold Runner System:Cold Runner / Hot Runner

Mold Gate Options:Slide Gate, Sub Gate, Pin-point Gate

Cavity:Single or Multi-Cavity

Design Software Supported:UG, PROE, CAD, SOLIDWORKS

Molding Equipment Used:CNC, Wire Cutting, Milling Machine, EDM

Compatible Raw Materials:ABS, PP, PC, PA6, PA66, PVC, POM, PMMA, PS, etc.

Packaging Method:Wooden pallet or carton

OEM Services:Available—please provide 2D/3D files or samples

Lead Time:Approximately 30 days

One-Stop Service for Tooling

– Initial Consultation: Assess client needs and provide expert advice on design, material selection, and tooling requirements.

– Custom Design: Create tailored designs based on client specifications, utilizing advanced CAD and 3D modeling tools.

– Tooling Fabrication: Manufacture precision molds and tooling using high-quality materials and state-of-the-art machinery.

– Prototype Development: Produce and refine prototypes to validate designs and ensure they meet client expectations.

– Comprehensive Testing: Conduct rigorous testing to verify mold performance, including functionality, durability, and accuracy.

– Surface Finishing: Apply various surface treatments such as polishing, coating, and texturing to achieve desired aesthetics and functionality.

– Production Readiness: Prepare molds for mass production, including final adjustments and quality checks.

– Logistics Management: Handle the complete logistics process, including packaging and shipping to ensure timely and safe delivery.

– Installation Support: Provide guidance and assistance with mold installation and setup to integrate seamlessly into client production lines.

– Quality Assurance: Implement stringent quality control measures throughout the process to ensure all products meet industry standards and client specifications.

– After-Sales Service: Offer ongoing support for maintenance, troubleshooting, and modifications to ensure long-term satisfaction and optimal performance.

Application

-

Medical:

– Our molds and tooling solutions are essential for manufacturing high-precision medical components, including surgical instruments, diagnostic devices, and implantable medical products. These tools are designed to meet stringent medical standards, ensuring biocompatibility, durability, and exacting tolerances required for safe and effective medical applications.

-

Automotive:

– In the automotive industry, our mold and tooling services support the production of critical components such as engine parts, interior trims, dashboards, and exterior body panels. Our advanced tooling solutions ensure high performance, precision, and durability to meet the demanding quality and safety standards of the automotive sector.

-

New Energy:

– Our expertise in mold and tooling is pivotal for the new energy sector, particularly in the manufacturing of components for solar panels, wind turbines, and energy storage systems. We provide high-quality molds that enable efficient production processes, contributing to the development of sustainable energy solutions.

-

Drone:

– For the rapidly growing drone industry, we offer specialized molds and tooling for the production of drone frames, propellers, and other key components. Our solutions ensure lightweight, durable, and aerodynamically optimized parts, enhancing the performance and reliability of drones for various applications.

-

Aerospace:

– In the aerospace industry, precision and reliability are paramount. Our molds and tooling solutions are used to produce components for aircraft, satellites, and space exploration equipment. We ensure that every part meets the highest standards of aerospace engineering, contributing to the safety and performance of aerospace technologies.

-

Electrical Appliance:

– Our molds and tooling are essential for the production of various electrical appliances, including household gadgets, consumer electronics, and industrial equipment. We focus on delivering high-quality, durable, and precise components that ensure the efficiency and longevity of electrical appliances.

-

Battery Equipment:

– We provide specialized molds and tooling for the battery industry, supporting the production of battery casings, connectors, and other critical components. Our solutions ensure high precision and reliability, essential for the performance and safety of batteries used in various applications, including electric vehicles and portable electronics.

-

5G Device:

– As the demand for 5G technology grows, our molds and tooling services play a crucial role in manufacturing components for 5G devices. We enable the production of high-precision parts for smartphones, base stations, and other communication devices, ensuring that they meet the performance and connectivity standards required for 5G technology.