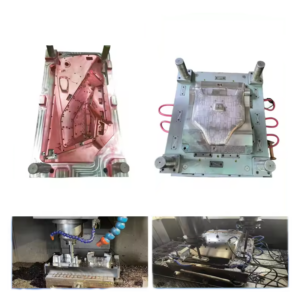

OEM Automotive Mold Manufacturing with No Intermediary Fees

Details:

| Mold Details | Product Description |

| Mould Core | P20, NAK80, SKD11, S316, S50C, S45C,718H, 2738 or customer specified |

| Standard | ISO9001:2008 |

| Plastic Material | HDPE, PP, nylon, PEEK, LDPE, ABS, styrene, acrylic, acetal, PE, PTFE, PEI, and PES |

| Other Materials | Rubber, Silicone rubber, LSR, Aluminum, Zinc, Copper, Metal, etc. |

| Size | According to your 2D, 3D Drawing |

| Package | Customized standard exported Wooden box packed |

| Experience | Over ten years experience in plastic injection mold making and plastic products production |

| To be Discussed | Mold decoration, injection molds, mold dimensions, processing technology, etc. |

| Lead Time | 25-40 days |

| Hot/Cold Runner | HUSKY, INCOE, YDDO, HASCO, DME, MoldMaster, Masterflow, Mastip, Taiwan made brand, etc. |

| Design & Program Softwares | CAD, CAM, CAE, Pro-E, UG, Solid works, Moldflow, CATIA, etc. |

| Equipments | High-speed CNC, Standard CNC, EDM, Wire Cutting, WEDM, Grinder, Plastic Injection Molding Machine (50-3000T) available |

| Range of Markets | Auto Parts Mould, Medical Parts Mould, Household Appliance Parts Mould, Power Tool Parts Mould, Daily Plastic Products Mould, Industrial Products Plastic Mould, Plastic Products Moulds |

Quality Assurance & Service:

– Lifetime After-Sales Support: We offer lifetime sales-after service for all injection molds, ensuring your complete satisfaction.

– Quick Response: Our team guarantees a 24-hour response time to address all your questions and comments promptly.

– Steel Quality Warranty: Our mold steel comes with a lifetime quality warranty. For 40HRC steel, we offer a 100K shots warranty, and for 45HRC steel, a 1000K shots warranty.

– Precision Manufacturing: All products are CNC machined and prototyped according to drawings. We conduct a 100% size check before shipment to ensure accuracy.

– Comprehensive Documentation: Our engineering team provides material certification, dimension reports, design checklists, and complete mold shipment details for your peace of mind.

Packaging Information:

– Parts Packaging:Parts can be packaged in bulk or individually, tailored to customer requirements, and shipped in sturdy export carton boxes.

– Mold Packaging:Molds are securely packed in standard export wooden boxes, and undergo fumigation process as per requirements, ensuring safe delivery.

Machine Overview:

– EDM (Electrical Discharge Machining):Utilized for precision shaping and machining of materials using electrical discharges.

-Band Saw Machine:Employed for cutting various materials with accuracy and efficiency.

-Lathe Machine:Used for shaping and machining cylindrical workpieces with precision.

-Milling Machine:Ideal for precise shaping and cutting of solid materials using rotary cutters.

-3D Printer:Enables the production of three-dimensional objects layer by layer using additive manufacturing techniques.

-Grinding Machine:Utilized for grinding and polishing materials to achieve precise dimensions and surface finishes.

-CNC Lathe Drilling Machine:Combines lathe and drilling capabilities with computer numerical control for high-precision machining operations.