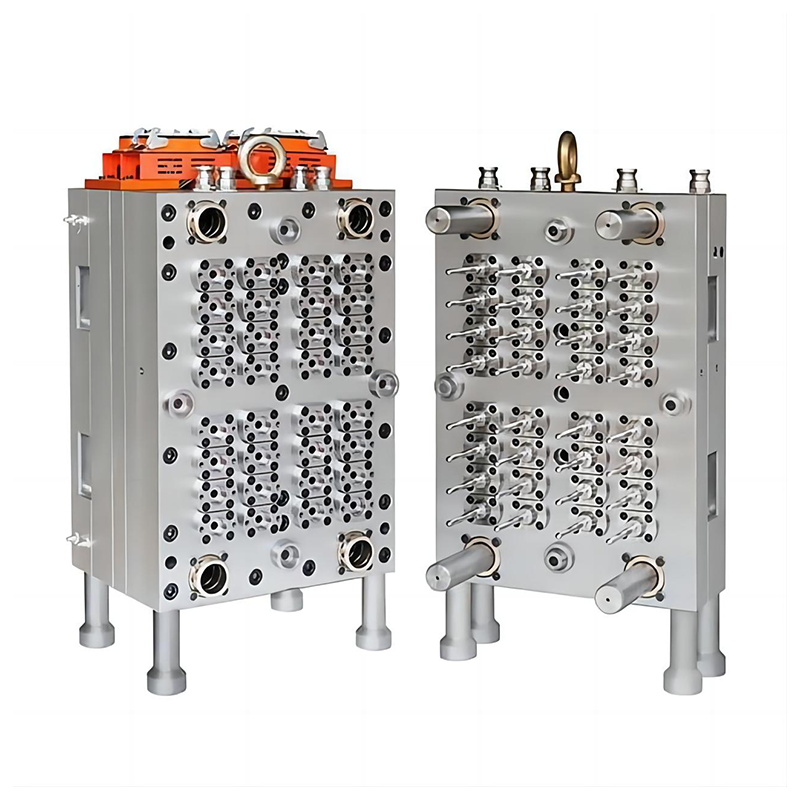

OEM Blood Collection Test Tube Mold Plastic Injection Molds

Our OEM blood collection test tube molds are designed with the highest standards to meet the specific needs of our clients. With advanced materials and technology, we provide reliable and efficient solutions for blood collection tube production.

Material Options and Market Preference

Material Choices:

Blood collection test tubes can be made from PET, PP, or glass. While glass is costly, PET is preferred over PP due to its higher vacuum rate and better water retention, making it the dominant material in the market.

High Precision Requirements:

Our molds meet stringent requirements for dimension and concentricity to ensure proper assembly and accurate volume measurement.

Advanced Runner System and Mold Materials

Husky Valve Gate Hot Runner System:

Equipped with the Husky valve gate hot runner system, our molds ensure precise control and temperature balance, essential for high-quality PET tube production.

Premium Mold Materials:

Mold Base Material: 420 stainless steel for robust and durable mold bases.

Mold Cavity Material: Austrian Bohler mold steel, known for its strength and longevity.

Customized Solutions and Production Environment

Tailored Solutions:

We offer bespoke solutions tailored to customer requirements, from initial product optimization and mold design to mass production.

Clean Production Environment:

Blood collection tube injection molding is conducted using electric or oil-electric hybrid injection molding machines in a 100K cleanroom to ensure optimal cleanliness and productivity.

Innovative Mold Design and Cooling System

Adjustable Core and Cavity Inserts:

Movable inserts in the core and cavity sides allow for easy adjustment of product dimensions, ensuring precision.

Efficient Cooling System:

Each cavity has an independent cooling water circuit, reducing the molding cycle time and improving efficiency.

Certification and Quality Assurance

Certifications:

Our molds are certified to ISO 9001 and IATF 16949 standards, ensuring quality and reliability.

Expert Design and Analysis:

Our R&D engineer team collaborates with experts to provide concept suggestions and professional mold design analysis from initial product models to production.

Manufacturing Excellence and Capacity

State-of-the-Art Facilities:

Manufacturing Site: 1600㎡ facility with over 30 processing machines, achieving mold precision up to 5μm and an annual output exceeding 1000 sets of molds.

Injection Workshop: Equipped with 30+ injection molding machines, a 100K cleanroom, and a 10K grade laboratory for comprehensive product assembly and quality control.

Industry-Leading Experience and Customer Focus

Experienced Management:

With 15 years of management experience, we have a well-established team dedicated to customer satisfaction.

Competitive Pricing:

We offer reasonable quotations after thorough discussions with our clients, ensuring that we meet their needs effectively and efficiently.