OEM Injection Molding for Medical Device Plastic Parts

Overview:

Our company provides comprehensive one-stop solutions tailored to meet your needs for custom plastic products. We specialize in every aspect of the process, from meticulous mold design to precise plastic mold manufacturing and high-quality injection molding. Our services also include expert assembly work, precise pad and silk screen printing, premium painting, ultrasonic welding, and meticulous packaging services. With our dedicated expertise and state-of-the-art facilities, we ensure excellence in every step of the production process, delivering top-quality results to our clients.

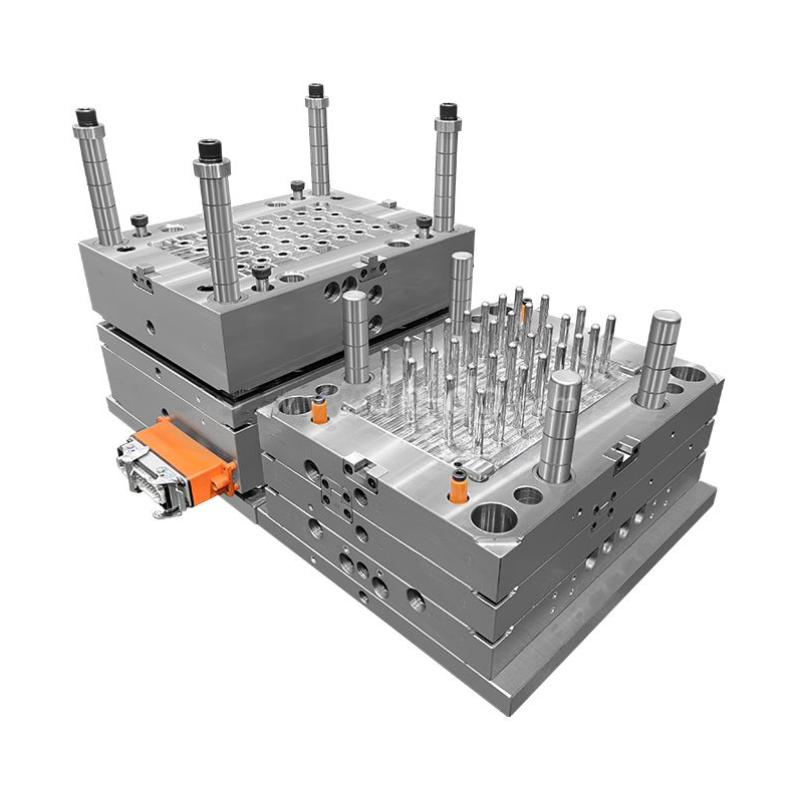

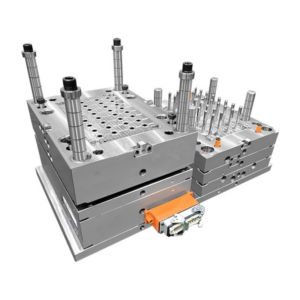

Product Details:

| Feature | Description |

| Place of Origin | Xiamen, China |

| Shaping Mode | Plastic Injection Mould |

| Material | Steel |

| Plastic Options | PP, PC, PA, PA6, ABS, PET, PVC, POM, etc. |

| Gate System | Cold Runner / Hot Runner |

| Ejection Method | Pin / Stripper Plate, etc. |

| A/B Plate | 1.1730 / P20, etc. |

| Tool Life | Prototype up to 1,000,000 shots |

| Mold Base | LKM standard mold base with HASCO component compatibility |

| Cavity & Core | P20, H13, NAK80, S50C, S136, 738H, etc. |

| Surface Finish | Polish, Texture, Heat Treatment, etc. |

| Cavities | Single, Multiple, or Family molds |

| Lead Time | 3 to 8 weeks |

Ordering Process:

1.Contact Us:

– Reach out to our sales team via email or phone with your inquiry or RFQ (Request for Quotation).

– Professional consultation provided promptly to meet your plastic molding needs and offer competitive pricing.

2.Submit Design:

– Provide 2D/3D designs or samples for accurate quoting and analysis.

3.Order Confirmation:

– Place a purchase order and make the required deposit.

4.Tooling Design:

– Conduct part mold draft analysis and finalize tooling design for client approval.

5.First Trial Mold:

– Manufacture the initial trial mold and send samples for client evaluation.

6.Quality Control:

– Review samples for quality. If not meeting standards, perform tooling modifications.

7.Production Process:

– Upon approval, commence steel material processing, including CNC, EDM, milling, and drilling.

8.Final Design Review:

– Review the finalized design before proceeding further.

9.Trial Production:

– Conduct trial production and finalize assembly.

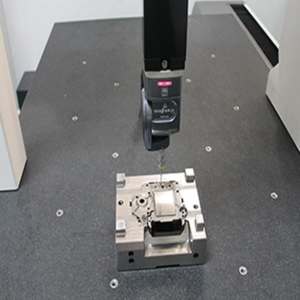

10.Quality Assurance:

– Perform quality checks and ensure product meets specifications.

11.Packaging & Shipment:

– Package the products securely and arrange for shipment.

12.After-Sales Service:

– Provide continuous support and assistance even after delivery to ensure customer satisfaction.

Injection Molding Workshop: