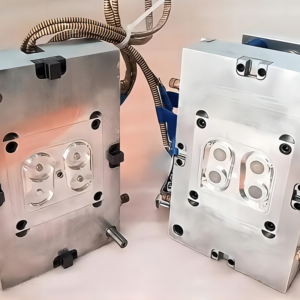

OEM Liquid Silicone Injection Mold For Medical Products

Basic Information:

– Steel Hardness: 20-60 HRC

– Treatment: Pre-Harden, Nitriding, Heat Treatment, Quenching

– Cavity Quantity: Single-cavity / Multi-cavity

– Mould Life: 500K – 5 million shots at least

– Design Software: UG, CAD, 3D MAX, PRO-E, Solid Works, etc.

– Process: CNC, High-Speed Carve, EDM, Wire-Cutting, Drill, Polish, etc.

– Quality: ISO9001:2000 Certificate

– Lead Time: 10-30 workdays, depending on the different products

– Package: Wooden Case Package or according to customer requirements

Disadvantage of Cold Runner without Needle Valve:

- Casting occurs(material overflow)

- Material will be solidified in cold nozzle and difficult to clean

- Liquid silicone rubber material will leave on the runner after picking out the waste cured material

- Difficult to control the amount of material injection

Customization Service for Molds

– Design Consultation:Collaborate with clients to understand specific design requirements and preferences.

– Technical Drawings:Create detailed technical drawings and specifications based on client input.

– Material Selection:Assist in choosing appropriate materials for both the mold and the final product to ensure optimal performance.

– Tooling Development:Develop custom tooling and molds tailored to meet precise specifications and production needs.

– Prototype Production:Produce prototypes to validate design, functionality, and material choices before full-scale production.

– Mold Fabrication:Utilize advanced manufacturing techniques to create high-quality, durable molds.

– Surface Finishing:Apply various surface treatments, including polishing, coating, and texturing, to meet aesthetic and functional requirements.

– Testing and Validation:Conduct rigorous testing of molds to ensure they meet quality standards and performance expectations.

– Adjustments and Iterations: Make necessary adjustments and refinements based on prototype testing and client feedback.

– Production Support:Provide ongoing support throughout the production process, including troubleshooting and maintenance.

– Quality Assurance: Implement stringent quality control measures to ensure the molds meet industry standards and client specifications.

– Delivery and Installation:Manage logistics for timely delivery and offer installation support to ensure seamless integration into the production line.