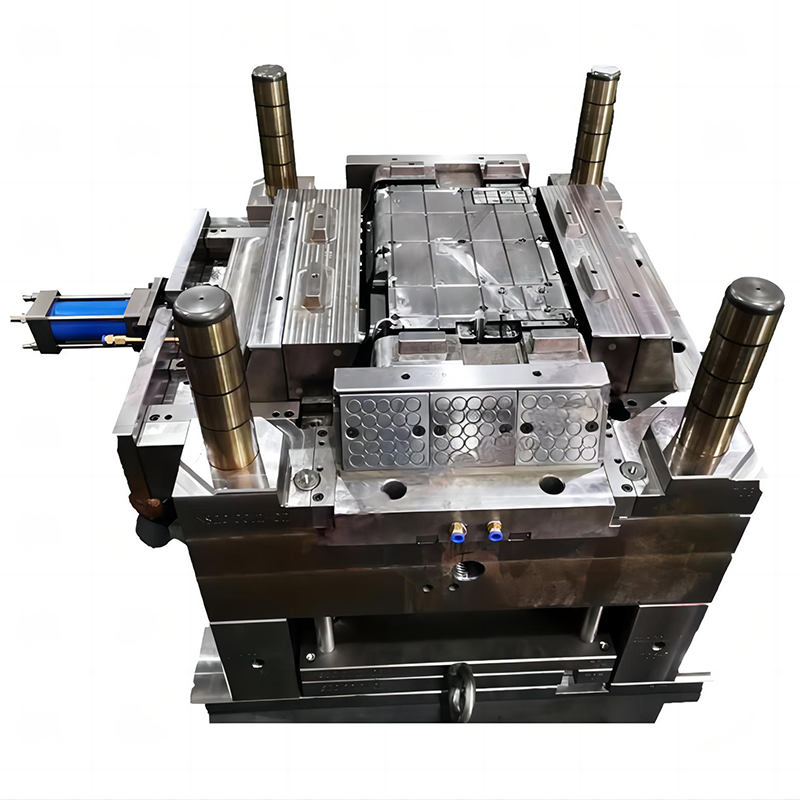

OEM Medical Devices Multi-Cavity Injection Mold Designer

Introducing our advanced plastic medical device molds and injection molding solutions designed specifically for the medical industry. Our expertise includes the manufacturing of a wide range of medical device molds, including but not limited to medical injection pumps, nutrition pumps, gastric lavage machines, infusion pumps, and suction pumps. We ensure the highest standards of quality and precision in our products, meeting the stringent requirements of the medical field.

Mold Material

Our molds are constructed using high-grade materials such as P20, P20HH, H13, 2738, NAK80, and 2316 to ensure durability and reliability. These materials are chosen to withstand high production volumes and provide a long mold life.

Cavity and Runner Options

We offer both single and multi-cavity molds to suit various production needs. Additionally, our molds can be designed with hot or cold runners based on the specific requirements of the project.

Mould Base Brands

We utilize reputable mould base brands such as LKM, HASCO, DME, and self-control options, ensuring a robust and dependable foundation for our molds.

Mould Life

Our molds are built to last, with a lifespan ranging from 300,000 to 1,000,000 shots, depending on the material and application.

Plastic Materials

We work with a variety of plastic materials, including ABS, PC, PMMA, PP, PBT, PE, and Nylon, ensuring compatibility with a wide range of medical device applications.

Design Software

Our design team employs advanced software tools such as UG, Pro-E, SolidWorks, and AutoCAD to create precise and efficient mold designs.

Tolerance

We maintain strict quality control with a tolerance of up to 0.02 mm, ensuring the highest level of precision for medical device components.

Product Appearance and Quality

The appearance of medical device products is critical. Most of our medical device molds feature dermatoglyph surfaces, which require flawless finishes without scratches or assembly misalignments. We utilize several techniques for texturing the mold surface, including sandblasting, chemical corrosion, and electro-discharge machining, to achieve the desired fine lines and textures.

Complex Mold Structures

Our medical device molds often incorporate complex features such as multiple sliders and inclined ejection structures to accommodate the intricate designs of medical device components. This ensures precise assembly and functionality of the final product.

For further information and to discuss your specific requirements, please contact us.