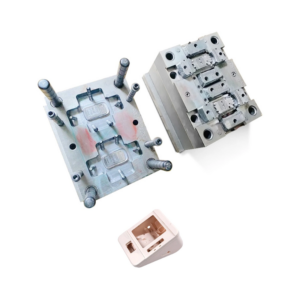

OEM Plastic Injection Mold for Blood Pressure Monitor Shell

| Item | Detail |

| Mould Material | P20, 718, NAK80, S316H |

| Steel Hardness | Vacuum quenching, nitriding, HRC41-47, HRC46-50, HRC60 |

| Mould Cavity | Single / Multi |

| Runner System | Hot / Cold |

| Injection Machines | Model options based on product precision: 100T, 128T, 150T, 200T, 250T, 368T, 450T |

| Inspection | 100% QC and QA inspection before shipping |

| Fast Mould Design | Completed within 1-3 working days after receiving customer drawings |

| Lead Time | Plastic moulds: 3-6 weeks post mould design confirmation |

| Mould Testing | Comprehensive testing before shipment; trial run videos available |

| Minimum Order | Small injection moulding orders accepted |

| Production Capacity | 50 sets/month |

| CAD for Quote | STEP & DWG formats |

| Mould Life | 100,000 – 500,000 shots |

| After Sales Service | Experienced staff available for support (over 10 years of experience in the field) |

Surface Finish Options

Polishing Finish

Achieve a smooth and shiny surface with our precise polishing techniques, enhancing the appearance and feel of the final product.

Texture Finish

Add unique textures to your product’s surface for improved grip and a distinct look, tailored to your specific requirements.

Glossy Finish

Opt for a high-gloss finish for a sleek and modern appearance, perfect for products needing a premium look.

Painting

Customize your products with a variety of painting options, offering vibrant colors and durable coatings to match your design specifications.

Silk Print

Utilize silk printing for sharp, detailed graphics and text, ensuring high-quality and long-lasting prints on your products.

Rubber Painting

Apply a rubberized coating for a soft-touch finish, providing enhanced durability and a comfortable feel.

Project Workflow

RFQ & DFM

Receive project inquiry and perform Design for Manufacturability (DFM) analysis to provide accurate quotations.

Purchase Order & Solution Discussion

Confirm project details with the customer and finalize the best solution before issuing a purchase order.

Design Approval & Material Selection

Obtain approval on project designs and select suitable mould steel materials for production.

Mass Production & Parts Approval

Initiate mass production and conduct thorough inspections to ensure parts meet quality standards.

Mould Correction & Customer Feedback

Address any issues during production and gather feedback from the customer for improvements.

T1 Sample Delivery & Mold Trial

Deliver T1 samples with inspection reports for customer validation and conduct mold trials for optimization.

Mould Machining & Texturing

Complete machining and texturing processes to prepare the mould for production.

Other Information:

Shipping Methods: Sample orders are shipped via Express Courier, including DHL, FedEx, UPS, TNT, EMS, etc. For bulk orders, we offer shipping by Air, Sea, or Land.

Payment Terms: We accept TT, Western Union, PayPal, MoneyGram, and Escrow. If you prefer other payment methods, please let us know.

Warranty: We value every opportunity to collaborate and consider our customers as friends. Our production quality always matches the sample tested. In case of defective goods, we will promptly reproduce and replace them.