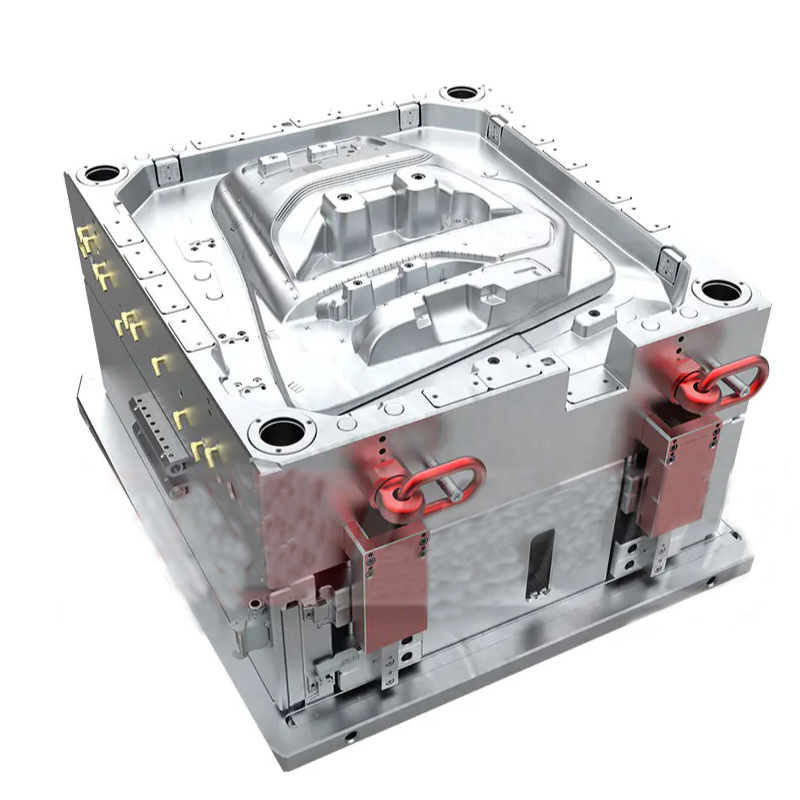

Plastic Injection Mold for Auto Car Door

Our experienced engineers are dedicated to providing comprehensive technical solutions for any issues that may arise during your mold operation. We ensure high efficiency and short delivery times at competitive prices.

You can send us your requirements or 2D/3D designs, and we will meticulously craft molds to meet your specific needs, whether it’s a spray cap mold or a plastic car door mold. We strive to exceed your expectations with precision and quality.

Features:

– Mold Name:Plastic Car Door Mold

– Plastic Material:PP+EPDM-TD15

– Mold Cavity/Core Steel:1.2738

– Runner/Gate System:Hot Runner Valve Gate

– Manufacture Time (Day):70 Days

– Mold Life:500,000 shots

– Demolding:Take By Robot

– Port: Xiamen

– Runner: Hot/Cold

– Payment Terms: L/C, T/T, Western Union, Money Gram

– Mould Making Service: OEM/ODM service available

– After Sales Service: Provided by staff with over 10 years of experience

– Good Packages: Packaged in strong wooden pallets to prevent damage during transportation

Our Service:

- Design for Manufacturing (DFM) Report

- Mold Flow Analysis

- Mold Design Documentation

- Manufacturing Progress Report (MPR)

- Quality Control (QC) Report

- Injection Parameter Sheet

- Testing Video

- Complimentary Samples

Production Process of Plastic Injection Mold for Auto Car Door:

- Requirement Analysis

– Collaborate with the client to understand the specific needs and requirements for the auto car door mold.

- Design and Engineering

– Create detailed 2D/3D designs using CAD software to develop the mold design, including DFM (Design for Manufacturing) analysis to ensure feasibility.

- Material Selection

– Choose high-quality steel or other materials for the mold cavity and core to ensure durability and precision.

- Mold Flow Analysis

– Conduct mold flow analysis to simulate the injection process, optimizing the design for efficient material flow and minimal defects.

- Mold Manufacturing

– Utilize CNC machining, EDM (Electrical Discharge Machining), and other precision tools to create the mold components based on the design specifications.

- Heat Treatment

– Apply heat treatment to the mold components to enhance hardness and durability.

- Assembly

– Assemble the mold components, including the installation of the hot or cold runner system as specified.

- Initial Testing and Tuning

– Perform initial tests to check for proper operation and make necessary adjustments to ensure the mold meets design specifications.

- Quality Inspection

– Conduct thorough quality checks, including dimensional verification and surface inspection, to ensure the mold meets all standards.

- Trial Injection Molding

– Run a trial injection molding process to produce sample parts, verifying the mold’s performance and the quality of the produced car door parts.

- Final Adjustments

– Make any final adjustments based on the trial results to ensure optimal performance and quality.

- Final Quality Control

– Perform a final quality control inspection to ensure the mold is ready for mass production.

- Packaging and Delivery

– Package the mold securely in strong wooden pallets to avoid any damages during transportation, and deliver it to the client.

- After-Sales Support

– Provide ongoing support and technical assistance to the client to address any issues that may arise during the mold’s operation.