Plastic Injection Molding for Kids’ Toy Handles and Lego Bricks

Overview:

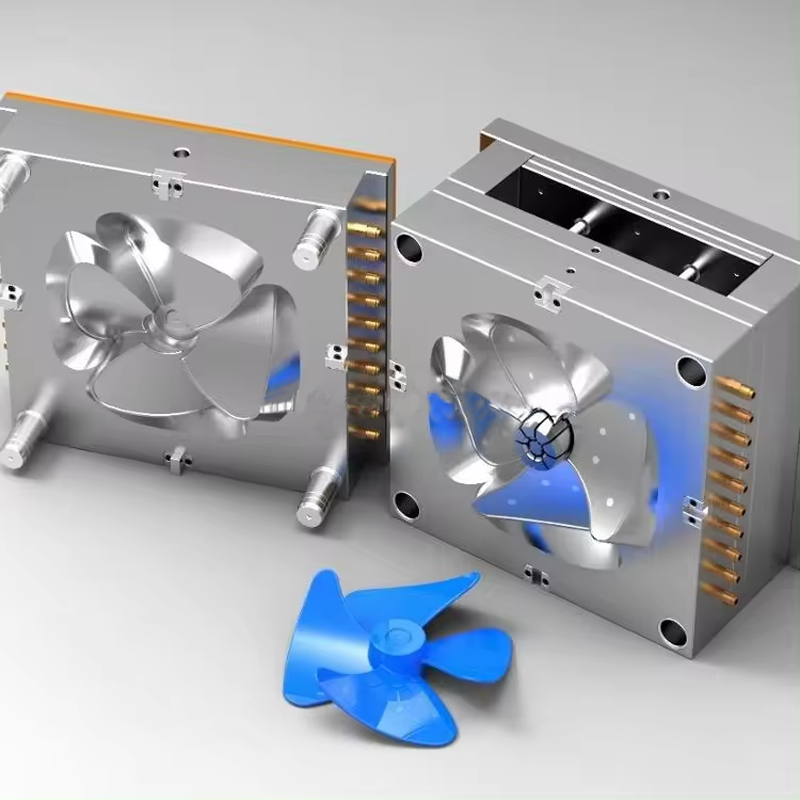

Plastic injection molding for kids’ toy handles and Lego bricks refers to the manufacturing process of creating plastic components, such as handles for toys designed for children and plastic bricks used in Lego building sets. This process involves injecting molten plastic material into a mold cavity under high pressure, where it cools and solidifies to form the desired shape of the toy handles or Lego bricks. The resulting products are durable, precise, and suitable for use in various children’s toys and construction sets.

Characteristics:

– Type of Enterprise:

– Specialized manufacturer of injection molds and plastic parts

– Services:

– Offers ODM, OEM, and design services based on client’s concept or produces molds and parts based on client’s drawings

– Design Software:

– Utilizes Solidworks, Pro-E, UG, CAD, Rhino, and other software

– Drawing Format:

– Supports Step, Igs, X_t, Dwg, Pdf, Stl (for 3D printing), and other formats

– Size:

– Customized according to client’s specifications

– Product Weight:

– Ranges from 1g to 5kgs

– MOQ (Minimum Order Quantity):

– Requires a minimum order of 100 pieces

– Production Ability:

– Capable of producing 10,000 pieces per day

– Assembly & Test:

– Operates a professional assembly factory with 6 assembly lines

– Packaging:

– Provides standard carton, pallet, or customized packaging

– Payment Details:

– Accepts various payment methods including T/T, L/C, D/A, D/P, Western Union, MoneyGram, Veem, Paypal, etc.

– Lead Time:

– Mold and sample production takes 3-4 weeks, while batch production is completed within 15 work days

– Shipping Method:

– Offers shipping via courier services (DHL, FedEx, TNT, UPS, EMS), Sea, and Air

– Prototype:

– Utilizes 3D printing, CNC, Laser cutting, and other techniques

Surface Treatment for Plastic Injection Molding:

- Painting:

Application of paint or coatings to enhance the appearance and add color to the surface of the plastic toy handles and Lego bricks.

- Printing:

Utilization of printing techniques to apply designs, patterns, or logos directly onto the surface of the plastic components.

- Texture:

Creation of texture on the surface of the plastic parts to improve grip, aesthetics, or functionality, achieved through mold texturing or post-molding processes.

- Polishing:

Mechanical polishing or buffing to achieve a smooth and glossy surface finish, enhancing the overall appearance and feel of the plastic parts.

- Plating:

Electroplating or chemical plating processes to deposit metallic coatings onto the surface of the plastic components, providing decorative and functional properties.

- Laser Etching:

Precision laser etching to engrave designs or markings onto the surface of the plastic parts, offering customization and branding opportunities.

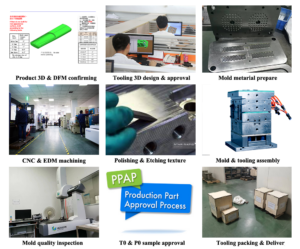

Production Process:

Protective Tips for Plastic Injection Molding:

- Material Selection:

Choose high-quality materials resistant to wear and tear, ensuring durability and longevity of the toy handles and Lego bricks.

- Design Considerations:

Incorporate rounded edges and reinforced structures in the design to minimize the risk of sharp edges or weak points that could pose safety hazards.

- Surface Finish:

Apply smooth and non-toxic surface finishes to the plastic components, enhancing their safety for children’s use and minimizing the risk of irritation or injury.

- Compliance with Safety Standards:

Adhere to relevant safety standards and regulations governing children’s toys, ensuring that the plastic injection molded products meet all necessary safety requirements.

- Quality Control:

Implement rigorous quality control measures throughout the manufacturing process to detect and address any defects or inconsistencies that could compromise the safety of the final products.

- Packaging:

Package the toy handles and Lego bricks securely to prevent damage during transportation and storage, minimizing the risk of sharp edges or protrusions that could cause harm.