Mould Manufacturing Process

– Inquiry Reception

– Receive customer inquiries promptly.

– Quotation and Details

– Provide price offers or detailed information within 16 hours.

– Drawing Submission

– Customers provide 2D/3D drawings and additional mold details.

– Order Confirmation

– Confirm order details including quality, price, material, delivery time, payment terms, etc.

– Production Preparation

– Prepare for production according to client’s requirements.

– Mold Detail Confirmation

– Clients confirm the specific details of the mold.

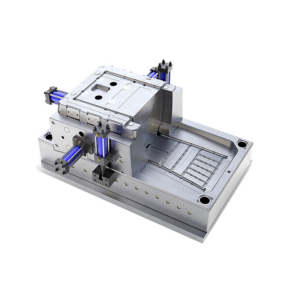

– Surface Shaping

– Perform operations such as drilling holes, high-speed carving, wire cutting, EDM, etc.

– Sample Testing

– Arrange for test mold production and send samples to customers for evaluation.

– Feedback and Adjustments

– If clients are not satisfied with the samples, provide feedback for adjustments.

– Repair and Finishing

– Conduct repairs, polishing, and texture application as necessary.

– Sample Approval

– Send revised samples until customers’ confirmation is obtained.

– Delivery

– Arrange delivery by sea, air, etc., as per customer preference.

State-of-the-Art Injection Factory

Our injection molding shop is equipped with 15 injection machines of varying sizes, capable of handling parts up to 1.5m x 1.2m in size with a maximum capacity of 1228 tons. This diverse range of equipment allows us to cater to various production needs, ensuring flexibility and efficiency in manufacturing.

Quality Assurance & Service:

– Lifetime After-Sales Support: We offer lifetime sales-after service for all injection molds, ensuring your complete satisfaction.

– Quick Response: Our team guarantees a 24-hour response time to address all your questions and comments promptly.

– Steel Quality Warranty: Our mold steel comes with a lifetime quality warranty. For 40HRC steel, we offer a 100K shots warranty, and for 45HRC steel, a 1000K shots warranty.

– Precision Manufacturing: All products are CNC machined and prototyped according to drawings. We conduct a 100% size check before shipment to ensure accuracy.

– Comprehensive Documentation: Our engineering team provides material certification, dimension reports, design checklists, and complete mold shipment details for your peace of mind.