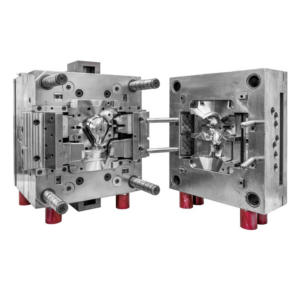

Our plastic overmolding tooling solutions are engineered for precision in multi-material and multi-component applications, ensuring flawless adhesion between substrates like thermoplastics and elastomers. Utilizing advanced CNC machining, EDM, and surface treatments, we create tooling that delivers exceptional durability and consistent quality. Each tool undergoes rigorous quality inspections throughout the manufacturing process to ensure optimal performance and longevity. Offering OEM services, we cater to custom designs and high-volume production. With our plastic overmolding tooling, you gain improved product performance, reduced assembly time, and enhanced aesthetics, all with a focus on cost-efficiency and timely delivery.

Basic Information

Place of Origin: Xiamen, China

Brand Name: OEM

Product Material: Metal

Material: Stainless Steel

Runner: Hot Runner / Cold Runner

Cavity: Single Cavity / Multiple Cavity

Surface Treatment: Polishing / Texture

Color: Customized Colors

Service: Customized OEM CNC Machining

Delivery Time: 20-25 Days

Quality: 100% Inspection

Drawing Format: 3D, STP, STEP, IGS, PRT, X_T

One-Stop Service for Molds

– Initial Consultation: Assess client needs and provide expert advice on design, material selection, and tooling requirements.

– Custom Design: Create tailored designs based on client specifications, utilizing advanced CAD and 3D modeling tools.

– Tooling Fabrication: Manufacture precision molds and tooling using high-quality materials and state-of-the-art machinery.

– Prototype Development: Produce and refine prototypes to validate designs and ensure they meet client expectations.

– Comprehensive Testing: Conduct rigorous testing to verify mold performance, including functionality, durability, and accuracy.

– Surface Finishing: Apply various surface treatments such as polishing, coating, and texturing to achieve desired aesthetics and functionality.

– Production Readiness: Prepare molds for mass production, including final adjustments and quality checks.

– Logistics Management: Handle the complete logistics process, including packaging and shipping to ensure timely and safe delivery.

– Installation Support: Provide guidance and assistance with mold installation and setup to integrate seamlessly into client production lines.

– Quality Assurance: Implement stringent quality control measures throughout the process to ensure all products meet industry standards and client specifications.

– After-Sales Service: Offer ongoing support for maintenance, troubleshooting, and modifications to ensure long-term satisfaction and optimal performance.