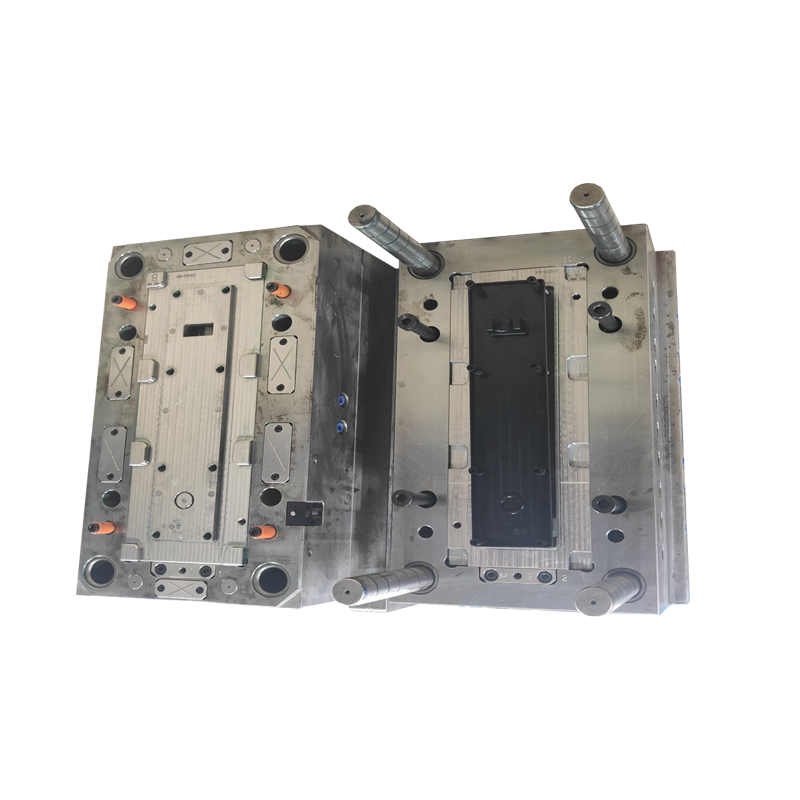

Premium High-Quality Custom Bathroom Faucet Switches Mold

Description:

Our precision mold for bathroom faucet switches is meticulously crafted using advanced injection molding technology. This innovative mold guarantees the production of high-quality switches for bathroom fixtures, characterized by durability and precision engineering. Designed to facilitate water conservation, the mold enables the creation of efficient and water-saving switches. With a focus on efficiency, precision, and consistency, our production process ensures the manufacturing of top-notch and environmentally friendly bathroom faucet switches.

Features:

| Item | Description |

| Mould Type | Plastic Injection Molding |

| Runner | Cold Runner |

| Steel Hardness | HRC38~42 |

| Mould Cavity | Single Cavity |

| Mould Installation | Manual |

| Molding Surface Treatment | Polishing |

| Mould Life | 100,000 to 300,000 Times |

| Plastic Product Material | PPS |

| Production Process | Injection Molding |

| Warranty Period | 1 Year or 100,000 Shots (Includes Free Parts or Service for Mold Issues within Warranty Period) |

| Mould Precision | ±0.01mm |

| Ejection System | Motor/Hydraulic Cylinder/Stripping Plate/Angle Pin, etc. |

| Cooling System | Water Cooling or Beryllium Bronze Cooling, etc. |

| Optional Plastic Materials | ABS, PPS, GPPS, HIPS, AS, MS, PMMA, PC, PA6, PA66, PA+GF, PVC, PP, PE, TPE, TPU, TPR, LCP, PBT, PETG, PC/ABS, POM, PPE, PPO, etc. |

| Mould Base | Standard Mould Base, LKM, HASCO, DME, etc. |

| Fast Mold Design | Within 1-3 Working Days after Receiving Customer’s Drawings |

| Mould Testing | All Moulds are Well Tested before Shipment, Video Testing Available |

| Mould Lead Time | Plastic Moulds: 3-4 Weeks after Mold Design Confirmation |

| Minimum Order | Small Orders Accepted |

| Mould Making Service | OEM/ODM Service Available |

| Mould Safe Packing | Strong Wooden Pallets to Avoid Damages during Transportation |

| Quality System | ISO9001, SGS, TS16949 |

| Specification | Depends on Clients’ Requirements |

| Origin | Xiamen, China |

Services Offered:

We offer a wide range of services, including:

– Mold Making

– Plastic Injection Molding

– Aluminum/Zinc Die Casting

– CNC Machining

– Sheet Metal Fabrication

– Surface Finishing

– Assembly and Packaging

Quality Guarantee:

– Lifetime sales-after service provided for all injection molds.

– Prompt 24-hour response to all inquiries and feedback.

– Mould steel quality warranty throughout its lifetime (40HRC steel: 100K shots warranty, 45HRC steel: 1000K shots warranty).

– CNC machined prototypes produced according to specifications and 100% size checked before shipping.

– Material certification, dimension report, and design checklist provided by our engineering team upon mold shipment.

Types of Molds We Specialize In:

- Household Parts Molds: Including Plastic Basket, Storage Box, Chair, and Table Molds.

- Appliance Parts Molds: Covering Fan, Air Conditioner, Washing Machine, TV, and Cooler Molds.

- Automotive Parts Molds: Including Bumper, Grill, and Interior Parts Molds.

- Thin-Wall Parts Molds: Covering Food Containers, Ice Cream Cups, and Thin-Wall Cups.

- Industrial Parts Molds: Such as Plastic Pallets, Dustbins, Crates, and Transportation Molds.

- Pipe Fitting Molds: Including Collapsible Core Elbow, PPR Pipe Fitting, PVC Pipe Fitting, and Tee Molds.