Premium Quality Custom Plastic Baby Bathtub Mold

Characteristics:

| Item | Detail |

| Product Material | ABS, AS, PP, PPS, PC, PE, POM, PMMA, PS, HDPE, TPE, TPU, etc. |

| Surface Finish | Polishing, Texture, Glossy, Painting, Silk Print, Rubber Painting, etc. |

| MOQ | 500 PCS |

| Packaging | Carton box or wooden case based on product weight and customer requirements. |

| Shipping | By sea or air as per customer’s requirements. |

| Export Country | Japan, Europe, USA, Mexico, Australia, Middle East, Korea, Asia, etc. |

| Typical Use | Housings, containers, caps, fittings, including: Power-tool housing, Electrical switches, Crates/Recycling boxes, Automotive dashboards, Television cabinets, Drug inhalation units, Automotive bumpers, Wheelie bins, Syringes, Telephone handsets, Washing-up bowls, DVDs, Bottle lids/closures, Battery casings. |

| Range of Markets | Industrial, consumer, food processing, aviation, seals/gaskets, lighting, packaging, filter, healthcare, telecommunications, mechanical, water treatment, appliance, recreation, lawn and garden, educational, oil and gas, government, construction, plumbing, surveillance, pumps, marine, motors, gears, RFID tags, electronics, and fasteners. |

Business Terms:

– Please provide detailed CAD or 3D drawings, or samples for reference.

– All products will be manufactured and delivered based on approved drawings provided by clients.

– We ensure strict confidentiality of our customers’ product information.

– Intellectual property rights of the product belong to the client and are unrelated to us.

Trade Terms:

– We offer EXW, FOB, CIF, or other required terms.

Payment Terms:

– Payment terms are 50% remittance by T/T in advance, with the balance of 50% due before shipment.

Lead Time (T0):

– T0 starts from the receipt of deposit in our account until the client confirms the design drawing.

Lead Time (T1):

– T1 starts after customer confirmation of the 3D mold drawing, until we arrange courier samples for client confirmation.

We offer a comprehensive ONE-STOP SOLUTION for customized plastic products:

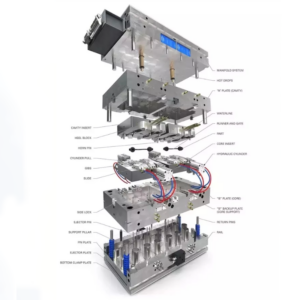

– Expert mold design and precise plastic mold fabrication.

– High-quality custom plastic injection molding.

– Additional services include assembly, pad printing, silk screen printing, painting, ultrasonic welding, and packaging.

Our goal is to provide top-notch services tailored to your specific plastic product needs.

Mold Shipment Process:

Quality Inspection:

– Thorough inspection of plastic mold installation to ensure structural integrity and part standards. Our project manager and quality inspection team follow company standards to guarantee product quality. Immediate corrective action is taken if any issues are identified to prevent errors. Continuous testing of cooling, hydraulic, and hot runner systems is conducted.

Pre-Delivery Check:

- Upon customer sample confirmation, our team leader checks the mold against the 3D design and customer requirements.

- Our inspector verifies the mold based on the provided files.

- Water and oil channel drawings are provided upon request, along with mold water transport pictures.

- After meticulous checking and approval, the mold is prepared for packing.

Mold Specification:

- Detailed instructions are filled in by the team leader.

- All mold accessories are packed into a wooden case.

- Mold trial report, usage instructions, temperature control box instructions, and quality certifications are prepared for the customer.

Mold Packing:

- Cavity and core are cleaned to remove any iron filings.

- Both inside and outside surfaces are sprayed with rust preventive paint.

- The mold is wrapped with plastic film.

- Finally, it is securely packed into a wooden case or onto a wooden pallet.