Features:

| Category | Details |

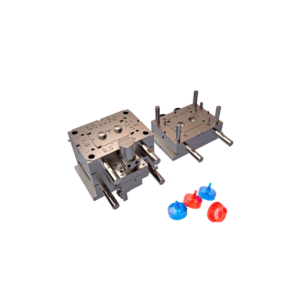

| Product | ODM Plastic Injection Molding |

| Plastic Materials | PS, ABS, PP, PVC, PMMA, PBT, PC, POM, PA66, PA6, PBT+GF, PC/ABS, PEEK, HDPE, TPU, PET, PPO, etc. |

| Standard | ISO 9001:2008 |

| Other Materials | Rubber, Silicone Rubber, LSR, Aluminum, Zinc, Copper, Metals, etc. |

| Quality | RoHS and SGS standards |

| Feature | Non-marking and Non-flash |

| Size | According to your 2D, 3D drawings |

| Color, Quantity, Unit Price, Tooling Cost, Tooling Size | To be discussed |

| Package | Standard exported wooden box, fumigation process if required |

| Mold Building Lead Time | T1, 15-25 working days, Part measurement report if required |

| Export Countries | Europe, Japan, USA, Australia, UK, Canada, France, Germany, Italy, etc. |

| Experience | 13 years in plastic injection mold making and plastic product production |

| Specialties | In-Mold Decoration, Injection Molding, Plastic Mold, Overmolding, 2K Molding, Die-Casting Mold, Thermoset Mold, Stack Mold, Interchangeable Mold, Collapsible Core Mold, Die Sets, Compression Mold, Cold Runner System LSR Mold, etc. |

| Mold Base | Hasco Standard, European Standard, World Standard |

| Mold Base Material | LKM, FUTA, HASCO, DME, etc., or as per customer requirements |

| Surface Finish | Texture (MT standard), High gloss polishing |

| Cavity/Core Steel | P20, 2311, H13, 2344, Starvax 420, 236, AdC3, S136, 2312, 2379, 2316, 2083, Nak80, 2767, etc. |

| Hot/Cold Runner | HUSKY, INCOE, YUDO, HASCO, DME, MoldMaster, Masterflow, Mastip, Taiwan brands, etc. |

| Mold Life | 5,000 to 1,000,000 shots, depending on working environment |

| Design & Program Software | CAD, CAM, CAE, Pro-E, UG, SolidWorks, Moldflow, CATIA, etc. |

| Equipment | High-speed CNC, Standard CNC, EDM, Wire Cutting, WEDM, Grinder, Plastic Injection Molding Machine for trial runs (50-3000T) |

Surface Treatment:

We use a variety of surface treatment, you have a variety of options.

Packaging for Plastic Molds:

- Apply a single layer of anti-rust oil.

- Wrap the mold with a protective film.

- Place the mold in a non-fumigation wooden box.

- Customize packaging according to customer specifications.

Delivery Method:

Sample orders are shipped via express courier services such as DHL, FedEx, UPS, TNT, EMS, etc. For bulk orders, we offer air freight, sea freight, or land transportation options.

Payment Terms:

We accept various payment methods including TT (Telegraphic Transfer), Western Union, PayPal, MoneyGram, and Escrow. If you prefer other payment methods, please inform us.

Warranty Period:

We value every opportunity for collaboration and consider our customers as valued partners. We guarantee that production quality matches the approved samples. In the event of defective goods, we will promptly reproduce and replace them.

Our Advantages:

Confidentiality

We prioritize your privacy by signing NDA documents to ensure that all information shared remains confidential. Our staff is trained on strict confidentiality protocols, and access to sensitive data is limited to necessary personnel only.

Proactive Communication

With years of collaboration with our partners, we guarantee high-quality products at reasonable prices. We not only ensure quality and timely delivery but also provide dedicated and proactive staff to address any issues that arise during the process.

Efficient Service

For urgent matters, we offer 24/7 support for timely responses. Our team is committed to replying to your emails within 12 hours or sooner, thanks to our energetic members who are always connected via smartphones. For better communication, please add us on WhatsApp or WeChat.

Competitive Pricing

We are eager to assist with your other projects that require outsourcing services, aiming to reduce your plant visit and transportation costs. Our goal is to secure the best prices for high-quality products, fostering trust and confidence between both parties.

Why Choose Us?

Comprehensive Design Analysis

Prior to project commencement, our engineers provide a complimentary DFM report and assist in updating CAD designs. Upon approval of drawings, we initiate SLA or CNC prototyping for structural testing.

Free Samples & Shipping

We offer competitive pricing upon confirmation of product details and quality requirements. We provide various solutions for trial orders or bulk production.

Dedicated After-Sales Support

We ensure quality assurance and provide free samples from our stock list for quality testing. For new customers, we offer additional replacements at no extra shipping cost if products do not meet agreed standards.

How to Order:

- Contact Us:

Provide 2D/3D drawings or samples for a quote.

- Quote Confirmation:

Receive and approve the quote.

- P.O./Deposit:

Submit purchase order and deposit.

- Part Mold Draft Analysis:

Review and confirm tooling design.

- Material Procurement and Processing:

Order steel materials and begin processing (CNC, EDM, Milling, Drilling).

- Design Review:

Conduct a design review to ensure accuracy.

- First Trial and Sample Submission:

Perform the first mold trial and send samples to the client for approval.

- Tooling Modification (if needed):

Make necessary modifications based on client feedback.

- Final Assembly and Trial Review:

Complete final assembly and conduct a trial review.

- Packing & Shipment:

Package the finished molds and arrange shipment.

- After-Sales Services:

Provide ongoing support and after-sales services.