Overview

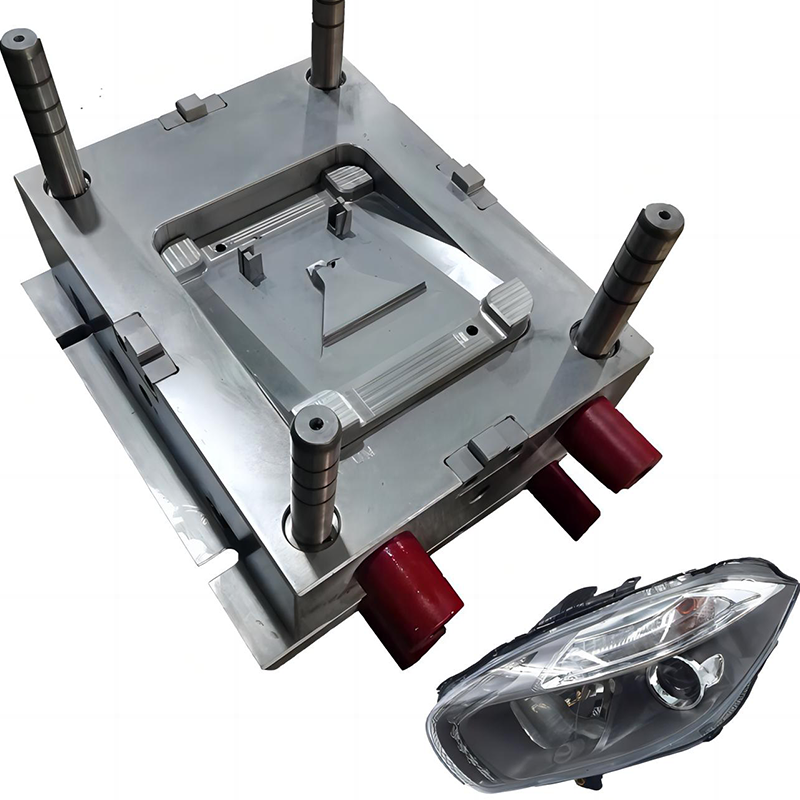

Our company specializes in supplying high-quality automotive moulds designed for the injection molding of car plastic parts. We use a single-cavity mold that can endure up to 300,000 shots with a cycle time of 95 seconds, ensuring efficiency and reliability in production.

Advantages of Injection Molding

Injection molding is a cost-effective method to produce precise and durable plastic components for the automotive industry. The process is quick, accurate, and capable of producing strong parts that meet the stringent requirements of car manufacturers. It is particularly suited for manufacturing small components like clips and fasteners, making it an ideal choice for automotive applications. Additionally, injection molding boasts high automation and repeatability, ensuring consistent quality in every batch.

Our Injection Factory Capabilities

Our factory, established in 2008, is equipped with 15 injection machines of varying sizes, with the largest being 1228 tons. This allows us to produce plastic parts with dimensions up to 1.5m by 1.2m. Our facility is capable of handling a diverse range of products, from sanitary parts to sports equipment, electronics, and automotive components. We also cater to custom requirements, including plastic containers and other specialized items.

Production Process

Customer Collaboration:

- Customers provide samples or 3D designs.

- Our designers create detailed 3D models for customer approval.

Mold Design and Fabrication:

- Finalize mold design based on approved 3D models.

- Order necessary steel materials.

- Conduct CNC processing and electrosparking.

- Assemble the mold.

Testing and Delivery:

- Test the injection mold.

- Produce plastic part samples and send them to customers for feedback.

- Upon approval, proceed with packing and delivery.

Customer Support:

- Gather customer feedback for continuous improvement.

- Handle new orders and custom requirements.

Peak Production Periods

Our busiest production periods are from March to June and September to January, during which we complete approximately 70 molds per month. We pride ourselves on our ability to meet tight deadlines while maintaining high standards of quality.

Design and Assembly Services

We offer comprehensive design services and final product assembly. Whether you provide us with samples or 3D models, our skilled team can bring your vision to life. Our end-to-end service ensures that you receive a complete solution, from initial design to finished product.

With years of experience and a wide range of capabilities, our factory is your ideal partner for automotive plastic parts injection molding. We are committed to delivering high-quality molds and plastic parts that meet your specifications. Contact us today to discuss your custom requirements and learn more about how we can support your production needs.