Supplying Battery Case Mold Battery Plastic Box Mould Design

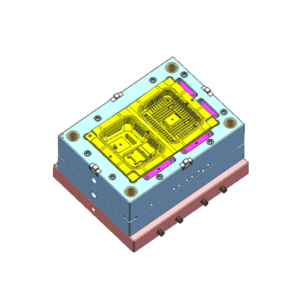

Customized Battery Box Mold Discover the future of battery case molds designed for the automotive industry. Our state-of-the-art battery box molds use beryllium copper to achieve rapid cycle times and exceptional cooling efficiency. Cutting-Edge Technology Experience the benefits of our innovative technology integrated into each car battery case mold. Our molds feature a sophisticated hot…

Product Details

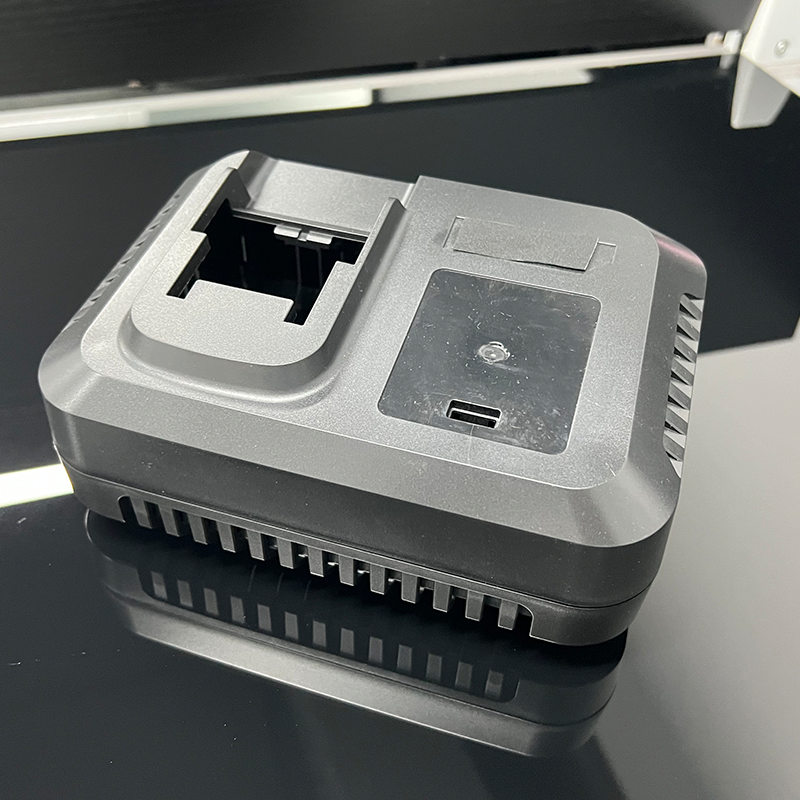

Customized Battery Box Mold

Discover the future of battery case molds designed for the automotive industry. Our state-of-the-art battery box molds use beryllium copper to achieve rapid cycle times and exceptional cooling efficiency.

Cutting-Edge Technology

Experience the benefits of our innovative technology integrated into each car battery case mold. Our molds feature a sophisticated hot runner system and a strategic stripper plate mechanism, ensuring high-speed production and fully automatic demolding.

Superior Materials

Our molds are crafted from premium materials, primarily ABS and PP, ensuring durability and longevity. These materials set a high standard for every molded battery container.

Global Reach, Local Expertise

With a significant annual production capacity, our molds are exported to clients worldwide. Our precision plastic molding expertise makes a global impact, showcasing our commitment to innovation and quality.

Customer Satisfaction

Our clients appreciate the speed and efficiency of our molds, especially the seamless and automated demolding process. We are dedicated to setting new standards in customer satisfaction.

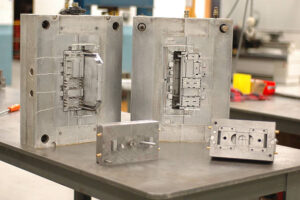

Consistent Lattice Size Control in Battery Case Molds

Ensuring uniform lattice size in battery case molds is crucial for flawless production. Loose fits can cause expansion during charging, while tight fits can obstruct the process. Here’s how we achieve precise size control:

Expertise and Precision

With over 15 years of experience, we have perfected our approach to maintaining the ideal lattice size. We avoid issues by finding the right balance in dimensions.

Mold Flow Analysis

Our engineers start with a detailed mold flow analysis to predict any potential deformations during production. This step is essential for understanding and controlling the molding process.

Strategic Injection Points

Based on the mold flow analysis, we strategically choose injection points to maintain an optimal injection balance. This ensures that each lattice size meets the specified standards.

Efficient Cooling Design

Our dense mold waterway design enhances cooling efficiency, ensuring rapid and uniform cooling. This design helps maintain the desired lattice size for every battery case mold.

Our battery case molds represent the pinnacle of engineering and technology. With a focus on precision, efficiency, and quality, we deliver molds that meet the highest standards in the industry.