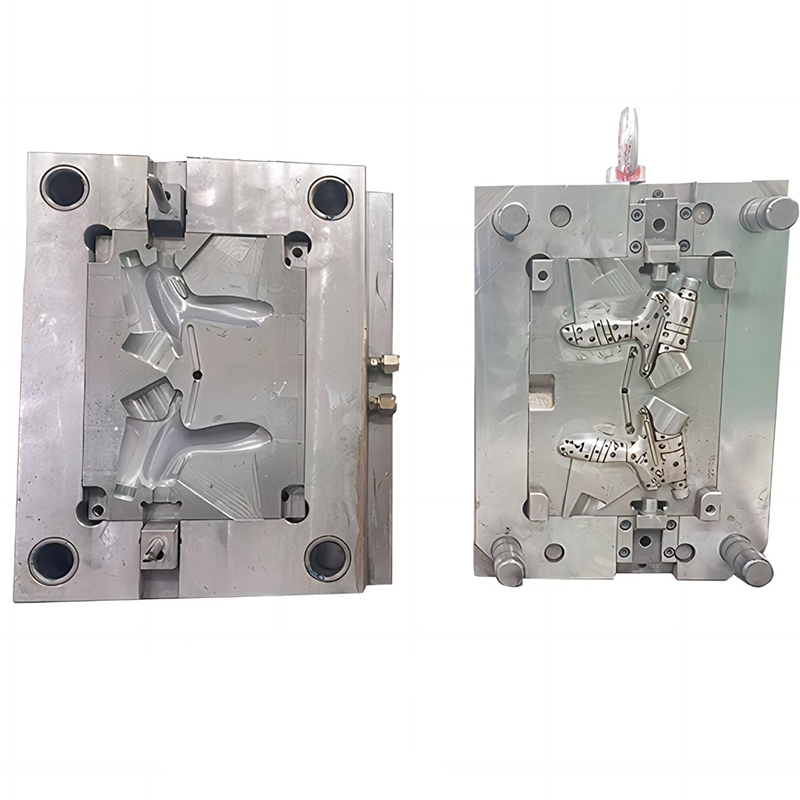

Precision Thermometer Plastic Mold Manufacturing

Introducing our precision-engineered medical infrared thermometer, crafted without harmful substances like mercury. We offer customized production tailored to your specifications.

Forehead Temperature Gun: Convenient and Accurate

Designed for ease of use, our forehead temperature gun provides accurate measurements within 1 second. It features a non-contact design to prevent cross-infection and is safe for the eyes as it operates without laser points. Ideal for a wide range of applications, including homes, hotels, libraries, large enterprises, hospitals, schools, and more. It can also measure object, liquid, and room temperatures.

Experienced Manufacturer with Advanced Equipment

With over 15 years of expertise in manufacturing non-contact infrared thermometer parts and molds, we utilize advanced world-class machining equipment to ensure high efficiency, precision, and durability. Our one-stop precision injection mold manufacturing facility handles everything in-house, from mold design and injection molding to shipment, ensuring seamless solutions for all your injection mold and molding needs.

Advanced Production Process

Manufacturing Capabilities

Our manufacturing facility is equipped with cutting-edge machinery and technology to ensure the highest standards of production. The process begins with meticulous mold design, utilizing advanced CAD software to create precise and efficient molds. These designs are then brought to life using our world-class CNC machining centers, which guarantee accuracy and consistency in every part.

In-House Production

Once the molds are created, our injection molding process takes over. We use high-performance injection molding machines that offer superior control over the molding process, ensuring each part meets stringent quality standards. Our facility also features automated assembly lines, enhancing production speed and efficiency while minimizing human error.

Quality Assurance

Throughout the entire production process, we implement rigorous quality control measures. Every stage, from initial design to final inspection, is monitored to ensure that all products comply with international standards and customer specifications. Our commitment to quality is reflected in the durability, precision, and reliability of our thermometers and medical device parts.