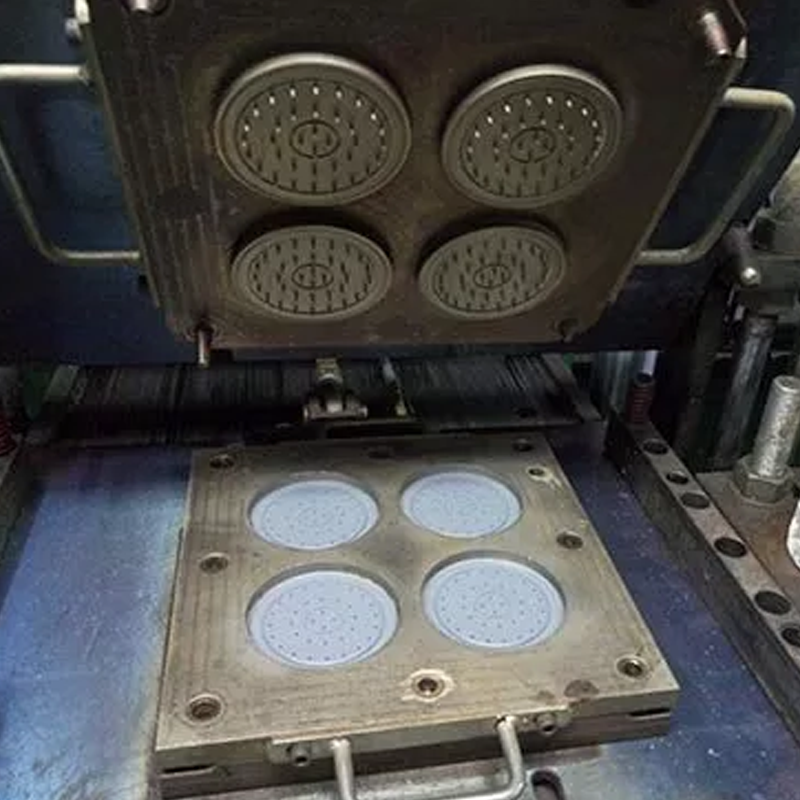

Top-Quality OEM Custom Silicone Shower Nozzles Mold

Overview:

The Silicone Shower Nozzle Injection Mold is a high-precision tool engineered for producing silicone shower nozzles. Designed with expertise, it enables the creation of nozzles featuring a clog-resistant design and easy maintenance. This mold supports the production of eco-friendly shower accessories using silicone materials that meet ROHS, SGS, ISO, FDA, and LFGB standards. These nozzles enhance the shower experience with spa-like comfort and contribute to a modern bathroom aesthetic. The mold’s efficiency and temperature resilience ensure the manufacture of durable and reliable silicone shower nozzles.

Key Features:

Mold Type: Shape Mold, Injection Mold

Surface Finish Options: Polishing, Sand Blasting, Painting, Anodizing, and more

Applications: Household Appliances, Home Use

Specifications: Custom Made

Installation Method: Fixed

Runner System: Hot/Cold Runner

After-Sales Service: 12 Months Warranty

Customization: Manufactured on Demand

Advantages: Fast Delivery, Precise Matching

Place of Origin: Xiamen, China

Materials Used: High-Quality Materials including ABS, PC, PVC, TPU, PP, PE, PLA, PET, TPE, Silicone, Carbon Fiber, etc.

Supported Drawing Formats: STEP, STP, IGS, DWG, PRT, PDF, STL (for 3D printing), and more

Surface Treatments

- Polishing

– Achieves a smooth, refined surface, enhancing the silicone shower nozzles’ aesthetic appeal.

- Texture Coating

– Adds grip and visual appeal, providing a tactile and stylish finish.

- Mirror Finish

– Utilizes advanced techniques for a sleek, high-quality, mirror-like surface.

- Sandblasting

– Creates a matte, textured surface, improving both visual and tactile qualities.

- Matte Finish

– Provides an understated, sophisticated look to the final product.

Our Services

- Instant Quotes

– Fast online quotes with easy file uploads and customizable options for materials, finishes, and lead times.

- Quality Assurance

– ISO 9001:2015 certified production ensures top-quality sheet metal with thorough material and dimensional inspections.

- Robust Manufacturing

– Extensive capabilities in Chinese factories offering a wide range of materials, finishes, and high-volume production.

- Engineering Support

– 24/7 online engineering assistance providing customized solutions and design optimization to reduce costs.

- Material Versatility

– Wide selection of metals and synthetics to meet diverse project requirements.

- On-Time Delivery

– Streamlined production processes ensure timely delivery of quality sheet metal components to meet your deadlines.