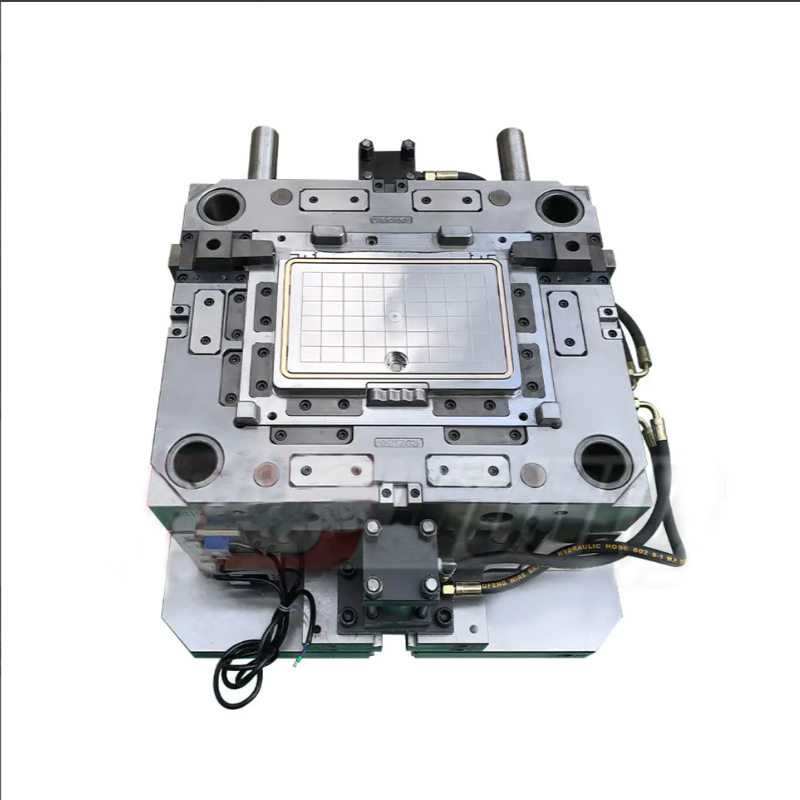

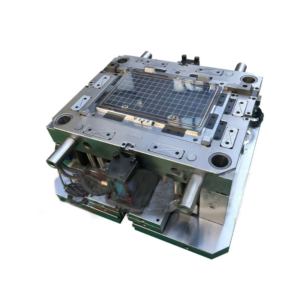

Top Selling Durable Custom Electric Meter Box Mold Tooling

Your Comprehensive Plastic Molding Solution:

- Diverse plastic product manufacturing capabilities.

- Rapid prototyping services available.

- Safe and efficient delivery.

- Competitive pricing for high-quality products.

- OEM support provided.

- Exceptional customer service.

- Welcoming of custom designs and specifications.

- Extensive experience in mold production design and management.

- Commitment to excellent after-sales support.

Production Workflow:

- Material Preparation

- Drilling

- Milling

- Lathe Machining

- EDM (Electrical Discharge Machining)

- Grinding

- Die Assembly

Surface Finishes:

- Texture Finish (MT Standard)

Utilizes texture finishing according to MT standards, providing a textured surface for improved grip and appearance.

- High Gloss Polishing

Achieves a smooth, shiny surface finish, enhancing the aesthetic appeal of the electric meter box mold.

- Matte Finish

Creates a non-reflective surface with a subtle texture, reducing glare and providing an elegant appearance.

- Satin Finish

Provides a smooth and slightly glossy surface, offering a balanced appearance with moderate reflectivity.

- Brushed Finish

Creates fine parallel lines on the surface, giving a brushed metal appearance and enhancing visual appeal.

- Leather Grain Finish

Mimics the texture of leather, providing a unique and tactile surface finish for added grip and style.

- Embossed Finish

Adds raised patterns or designs to the surface, enhancing aesthetics and providing a tactile feel.

- Sandblasted Finish

Creates a textured surface by blasting fine abrasive particles, offering enhanced grip and a modern look.

Our Competitive Edge:

- Decades of Expertise

Over 20 years of specialized experience in mold design and production, exclusively crafted in Xiamen.

- Global Partnership

Close collaboration with local representatives ensures seamless technical communication and robust after-sales support for our international clients.

- Diverse Capabilities

Proficiency in custom plastic injection molding, silicone rubber molding, stamping die molding, liquid silicone rubber molding, and utilization of advanced systems like Mold Master, MasterFlow, LKM, and Incoe.

- Strong Collaborative Culture

Our cohesive teamwork with vendors ensures smooth operations and efficient project execution.

- Cost-Effective Solutions

Targeting niche markets, we provide end-to-end services at competitive rates for new projects.

- Specialized Expertise

Skilled in handling complex mold types, including undercut molds, unscrewing molds, high-gloss polished molds, interchangeable core molds, and more, catering to diverse production needs.