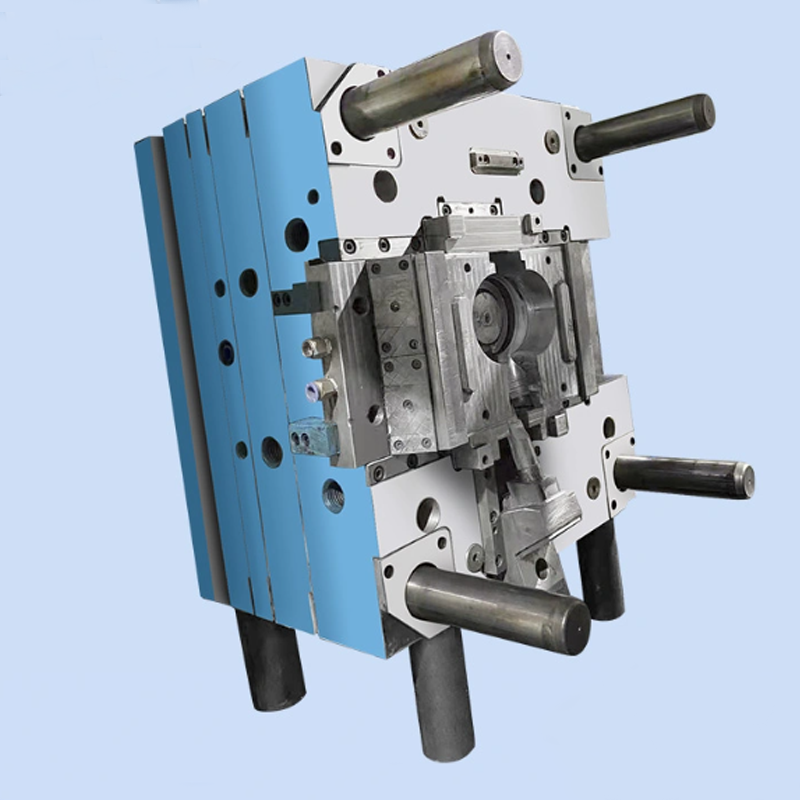

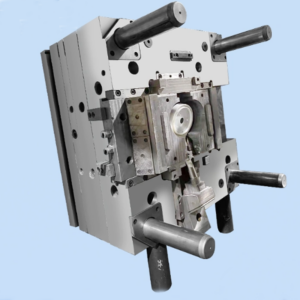

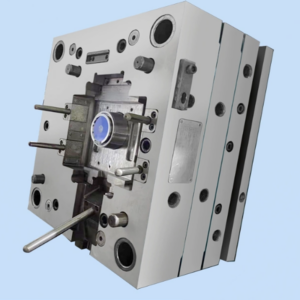

Two-Shots Mold for Shower Spray Nozzle with Different Sizes

In Xiamen, numerous manufacturers offer shower head nozzle injection molds, each with unique advantages tailored to specific models and purposes. Among them, Toolingsun stands out as a dedicated manufacturer specializing in the research and development, as well as the sales of injection mold products. Our expertise lies in producing shower spray nozzles, spray nozzles, filters, filter elements, and more. Backed by experienced technical personnel, advanced production technology, comprehensive testing procedures, stringent management systems, we ensure stable product quality and reliable performance.

Key Details:

Mold Cavity: Single

Plastic Material: ABS

Process Type: Single-Process Mode

Application: Household Appliances, Home Use

Runner: Cold Runner

Design Software: UG

Installation: Fixed

Certifications: CE, ISO

Standard: HASCO

Customization: Available

After-sales Service: 3 Years

Packaging: Customized or Color Box

Specifications: 290x285x90mm

Trademark: OEM/ODM

Origin: Xiamen, China

Production Capacity: 600 sets per year

Quotation Process:

- Requirements Gathering:

Provide 2D/3D drawings or samples to initiate the quotation process.

- Mould Design:

Mould design drawings will be prepared and sent for customer confirmation.

- Mould Manufacturing:

Commence mould manufacturing upon confirmation of the design.

- Mould Trial:

First shot samples will be produced for customer evaluation.

- Sample Confirmation:

Customers review and confirm the samples.

- Mould Modification:

If necessary, modifications to the mould will be made.

- Mould Delivery:

The mould will be delivered after receiving the third payment.

- After-Sales Service:

Enjoy free 12-month warranty service for added peace of mind.

Injection molding encompasses various techniques for manufacturing plastic and rubber products:

- Rubber Injection Molding:

Utilizes a rubber compound injected directly into the mold for vulcanization. Advantages include short molding cycles, high production efficiency, and excellent product quality.

- Plastic Injection Molding:

Involves injecting molten plastic into a mold to produce desired plastic parts through cooling and molding. This method is commonly used for various plastic products, with polystyrene being a popular choice.

- Overmolding and Insert Molding:

These processes involve combining multiple materials or components during the injection molding process to create a final product without further processing. Complex details such as bosses, ribs, and threads can be integrated in a single operation.

Toolingsun specializes in designing and manufacturing precision injection molds and custom molded plastic parts. From initial design and development to manufacturing, we provide comprehensive solutions for new product development.