Overview

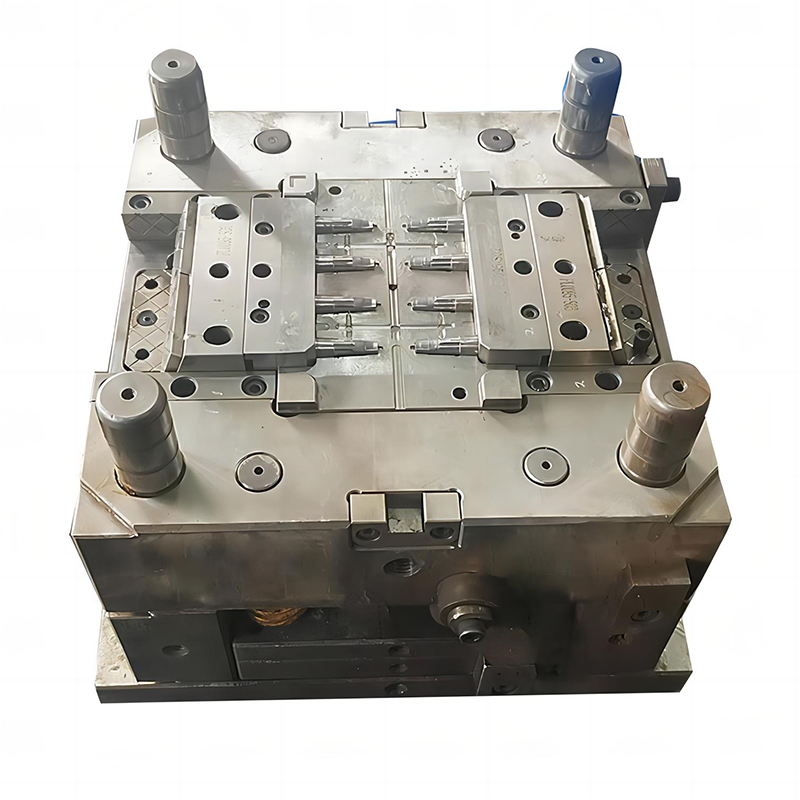

We present our high-quality precision mold designed specifically for manufacturing medical device joints. Utilizing top-tier plastic materials such as PS and mold steel NAK80, this mold ensures exceptional performance and durability. Designed with a cold runner and a slider structure, it provides a smooth ejection process and boasts a mold working life of up to 300,000 shot times.

Material and Structure

- Plastic Material: Polystyrene (PS) is chosen for its excellent performance in medical applications, ensuring biocompatibility and safety.

- Mold Steel: The mold is crafted from NAK80 steel, renowned for its hardness and precision, ensuring a long-lasting and high-quality mold.

- Runner System: The cold runner system is designed to be efficient and cost-effective, minimizing waste during the molding process.

- Mold Structure: Featuring a slider structure, this mold effectively handles undercut designs, ensuring smooth and reliable ejection of parts.

Durability and Efficiency

This precision mold is designed to deliver high efficiency and longevity. With an 8-cavity design, it maximizes production capacity while maintaining precision and quality in each piece. The mold’s working life extends up to 300,000 shot times, providing excellent return on investment and consistent performance over time.

Applications in Medical Devices

Medical-grade plastics, such as those used in our molds, are critical for manufacturing various medical products, including MRI shells, medical device joints, plastic syringes, and prosthetics. Their biocompatibility makes them suitable for components that come into contact with the human circulatory system. They also offer the necessary ductility, hardness, and precision required for intricate medical components.

Choosing the Right Medical-Grade Plastic

Selecting the appropriate medical-grade plastic is crucial due to the unique biocompatibility requirements of medical devices. Unlike traditional plastic polymers, medical-grade plastics are designed with biocompatibility in mind. Our joint laboratory can assist in matching your product needs with the suitable medical-grade plastic, ensuring both safety and performance.

Customized Precision Molding Solutions

We offer customized precision molding and molds tailored to your specific injection molding production needs. Our expertise ensures that each mold is designed to meet the exact specifications and requirements of your medical devices, providing high-quality and reliable components for critical medical applications.