Injection molded products are an essential part of our everyday lives. From the plastic utensils we rely on for our meals to the intricate components found in our electronic devices, injection molding has revolutionized the manufacturing industry. However, while this method has brought many benefits, it is not without challenges. At Toolingsun, we recognize that defects in injection molded products can significantly impact their quality and functionality.

In this blog, we will delve into common defects associated with injection molding and provide practical solutions to eliminate these issues. Understanding these defects will help enhance your product quality and customer satisfaction, whether you’re a seasoned manufacturer or just starting.

Understanding Common Defects in Injection Molded Products

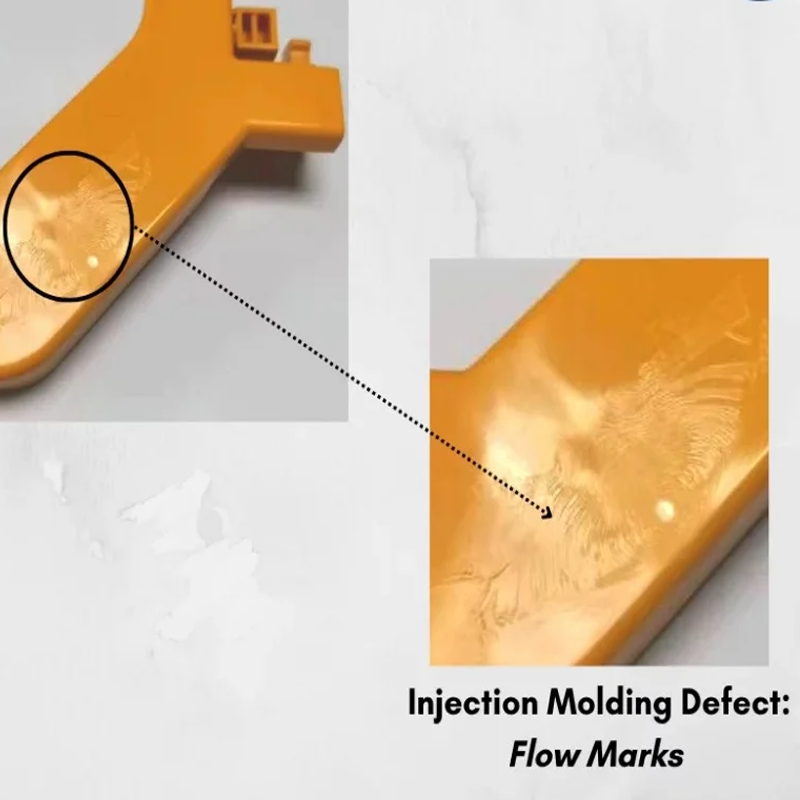

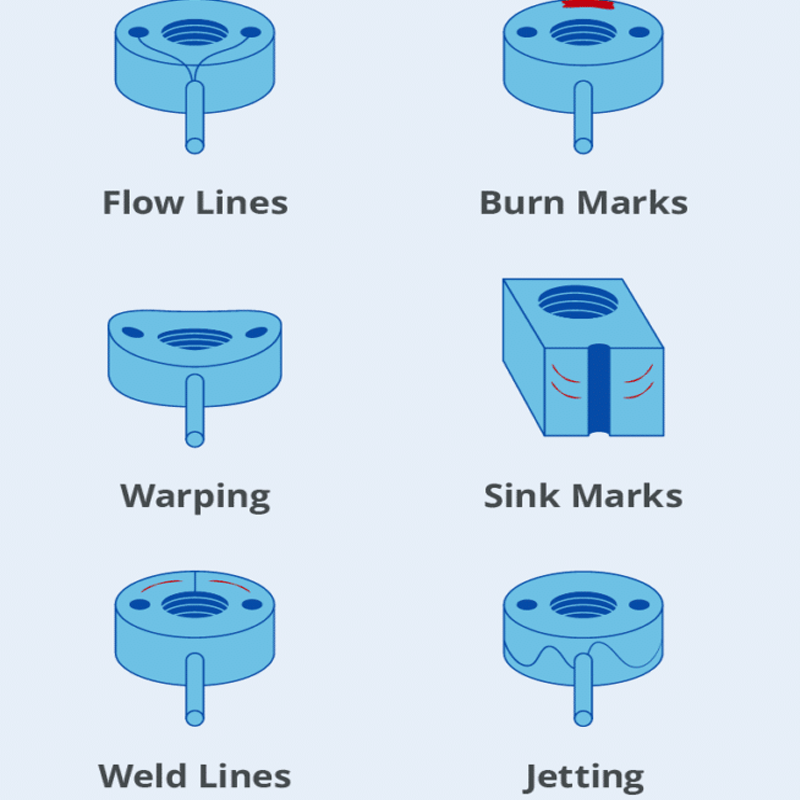

Injection molded products can suffer from various defects, each with its own implications for quality. Here are some of the most common defects you may encounter:

- Warping: One of the most prevalent defects, warping occurs when a product cools unevenly, leading to bending or twisting. This issue can arise from several factors, including improper cooling rates, inadequate mold design, or even the choice of materials used in the process. Warping not only detracts from the product’s appearance but can also hinder its functionality, rendering it unsuitable for its intended application.

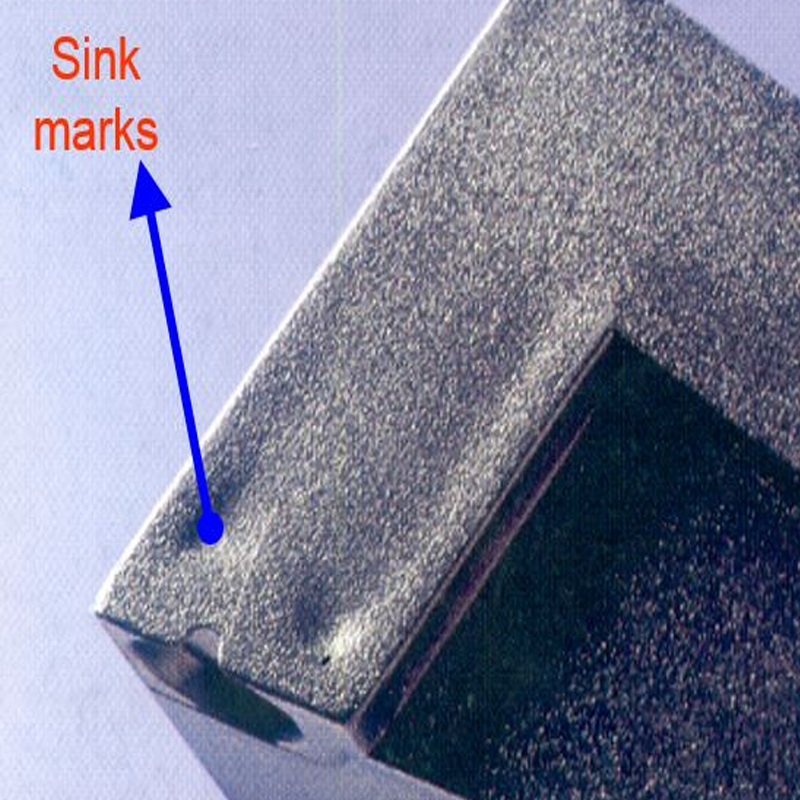

- Sink Marks: These are depressions that appear on the surface of molded products, typically caused by uneven cooling or insufficient packing pressure during the molding process. Sink marks can compromise the structural integrity of the product, making it more prone to breakage and reducing its aesthetic appeal.

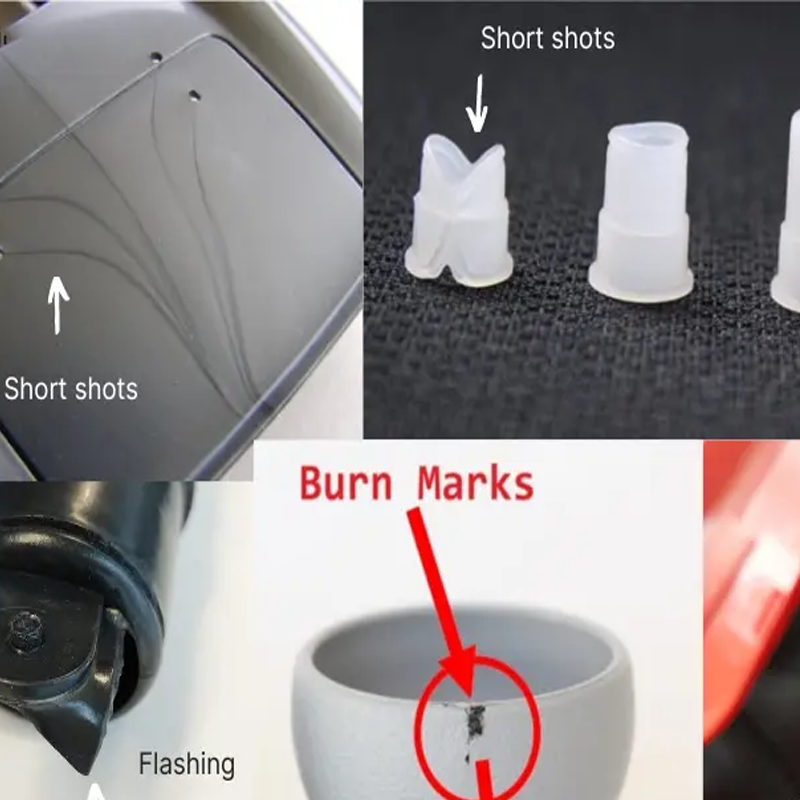

- Flash: Flash is another common defect that occurs when excess material escapes through tiny gaps between mold components during the injection process. This results in thin, unwanted projections along the edges of the molded part. Flash not only affects the overall aesthetics but can also pose safety risks due to sharp edges that may cause injuries during handling.

- Inadequate Filling and Poor Parting Line Alignment: Inadequate filling leads to incomplete parts with voids or gaps, which can impact both functionality and appearance. Poor parting line alignment, on the other hand, results in visible lines or misalignment on the product’s surface, which can be unacceptable in many applications.

- Black Spots: These unsightly blemishes are often caused by contamination during the manufacturing process. They can result from dust, dirt, or other foreign particles becoming trapped in the molten plastic. The presence of black spots can lead to customer dissatisfaction, as they detract from the product’s overall appearance and quality.

Addressing Warping

Warping is a significant concern in injection molding, and effectively combating it requires attention to several key factors:

- Mold Design: The first step in preventing warping is to ensure proper mold design. A well-designed mold should feature uniform wall thickness and adequate cooling channels to facilitate even cooling of the part. Incorporating design features such as ribs or gussets can help distribute stress more evenly throughout the product, reducing the likelihood of warping.

- Material Selection: Choosing the right material for your injection molded products is critical. Different plastics have varying shrinkage rates during the cooling process, which can contribute to warping. Selecting materials with low shrinkage rates or using additives that minimize shrinkage can significantly reduce warping risks.

- Processing Parameters: Optimizing processing parameters plays a crucial role in preventing warping. Controlling factors such as melt temperature, injection pressure, and cycle time can directly impact part quality. Monitoring and adjusting these parameters throughout production ensures consistent results and helps to minimize warpage.

- Post-Molding Processes: In some cases, employing post-molding processes such as annealing or stress-relieving techniques can help reduce residual stresses within the part. This can effectively prevent warping and improve the overall performance of the molded product.

Combating Sink Marks and Flash

Sink marks can undermine the structural integrity of a product. To combat sink marks, manufacturers should focus on the following strategies:

- Proper Mold Design: A mold designed for uniform filling of plastic material is essential. Implementing effective gating systems and venting techniques allows for proper packing pressure and helps to prevent sink marks.

- Quality Control of Process Parameters: Maintaining the correct temperature and pressure levels during the injection molding process is crucial. Regular monitoring and adjustments can help achieve consistent results and minimize sink marks.

When it comes to flash, here are some practical steps to reduce its formation:

- Optimize Mold Design: Ensuring that your mold has effective venting and gating systems will help excess material escape easily, minimizing the chances of flash formation. Using high-quality molds made from durable materials can also reduce wear and tear, which contributes to flash.

- Control Process Parameters: Keeping temperature and pressure levels within optimal ranges prevents excessive material flow that can lead to flash. Regular monitoring and adjustments are essential to maintain consistency throughout production.

- Post-Processing Techniques: Implementing post-processing techniques can help eliminate any remaining flash after molding. Utilizing trimming or cutting tools specifically designed for removing excess material should be done carefully to avoid damaging the product itself.

- Operator Training: Providing proper training for operators on mold maintenance and troubleshooting common issues will contribute significantly to reducing flash. Educating them about attention to detail and the importance of proper handling techniques is crucial.

Ensuring Adequate Filling and Proper Alignment

Inadequate filling and poor parting line alignment are common issues in injection molded products, but they can be resolved through careful attention:

- Mold Design: Ensuring that the mold is designed for uniform filling is paramount. Incorporating appropriate gating systems and venting techniques helps to facilitate adequate filling.

- Material Selection: Selecting the right plastic material is critical, as different plastics exhibit varying flow properties and shrinkage rates. Opting for materials with good flow characteristics and minimal shrinkage is key to achieving proper filling and alignment.

- Optimizing Processing Parameters: Maintaining optimal temperature and pressure levels during both heating and cooling stages will help avoid uneven filling or warping of the product. Regular checks and adjustments during the molding process will yield better results.

Eliminating Black Spots

Addressing the issue of black spots, often caused by contamination or inadequate mixing of materials, involves several steps:

- Clean Environment: Keeping the production environment clean is vital. Ensuring thorough cleaning of molds and equipment before production begins will minimize contamination risks.

- Quality Materials: Using high-quality raw materials and properly drying them before processing can help prevent black spot formation. Regular checks on incoming materials will assist in identifying potential sources of contamination.

- Optimize Mixing Processes: Paying close attention to mixing processes ensures that colorants and additives are adequately blended into the molten plastic. Investing in high-quality mixing equipment can greatly improve material dispersion.

- Regular Maintenance: Implementing a routine for cleaning and inspecting molds will help identify any potential sources of contamination or wear that may lead to blemishes on molded products.

- Adjusting Molding Parameters: Fine-tuning molding parameters, including temperature settings and pressure levels, will help ensure uniform melting and distribution of plastic material within the mold cavity.

Conclusion

At Toolingsun, we are dedicated to delivering high-quality injection molded products while minimizing defects. By focusing on proper design, careful material selection, and rigorous process control, we can help you achieve the best results in your manufacturing process. Understanding the common defects associated with injection molding and implementing the strategies outlined above can significantly enhance product quality and customer satisfaction.

If you have any questions or need further assistance, don’t hesitate to reach out to us! Your success is our priority, and we are here to help you every step of the way.