The automotive industry is fiercely competitive, and any inconsistency in production can lead to significant losses. Over time, such issues can damage your reputation and erode your customer base, impacting your profitability. However, did you know that manufacturing tooling can help you mitigate these risks and save money?

What are the advantages of mold manufacturing? Through this blog, we will explore this issue together. Read on to discover why minimizing tooling costs is just one of many advantages.

- Consistent High-Quality Production

Modern tooling techniques significantly reduce the risk of production errors, allowing you to consistently produce high-quality, defect-free products. Rapid tooling processes are more efficient than traditional methods, enabling you to use less material and energy, which reduces waste and saves money over time.

As tooling technology advances, your manufacturing capabilities will also improve, allowing you to adapt to industry changes and maintain a competitive edge.

- Precision and Uniformity in Complex Components

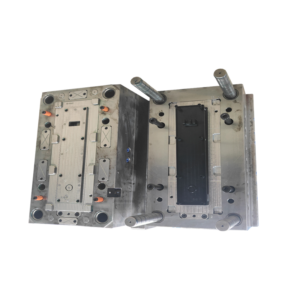

Advanced tooling enables the creation of intricate and superior designs with precise repetition. In the past, such complexity often led to production failures, but modern tooling ensures uniformity across all components.

Precision manufacturing allows for programmable devices that can replicate the same instructions for each build. Digital prototypes can be created before tooling begins, identifying potential failure points early in the process.

Ensuring uniformity and compliance with international standards enhances the quality of your products and expands your reach to a global market.

- Enhanced Durability and Longevity

Precision engineering through advanced tooling ensures that your products are durable and long-lasting. Consistent quality reduces the likelihood of batch failures, allowing you to design for longevity.

Modern tooling methods also allow for protective measures, such as anti-corrosion treatments, to be integrated into the production process.

Finding the Right Manufacturing Tooling Service

The benefits outlined are essential for staying competitive in the automotive industry. Partnering with a reliable tooling service like Toolingsun can help you leverage these advantages. Contact them today to take advantage of these advanced techniques.

Choosing the Optimal Rapid Tooling Process

While rapid tooling offers many benefits, it may not be suitable for every project. The main drawback is that the precision of prototypes or molded parts may not match that of conventional methods, depending on the methodology used. However, advancements in tools like 3D printers and CNC machines have significantly improved accuracy and precision.

The key to successful rapid tooling is finding a trusted expert. An experienced contract manufacturer will collaborate with you on your design and advise if rapid tooling is suitable for your project. They will consider factors such as:

- Your timeline for product market entry

- The need to test multiple materials

- The complexity and precision requirements of your design

- Your total development budget

- Whether you need a mold for large-scale manufacturing

Your responses will help determine if rapid tooling is appropriate. If conventional tooling is better, the manufacturer will devise a detailed plan to streamline the process without exceeding your budget. With their expertise, you can smoothly transition from prototyping to manufacturing.

As a mold manufacturing factory with more than ten years of industry experience, any of your ideas about molds can be turned into reality through us. We are confident that our high-precision molds will not let you down.